Are you interested in learning what a split point drill bit is?

Great.

You have arrived at the correct location!

Should include a drill in the toolset of any well-equipped home. They are one of the most versatile tools you can own.

A drill will come in helpful whether you’re making furniture, shelving, hanging art, or need to drill a hole.

It is critical to understand the drill bit to use. There are numerous drill bits, each with its own set of advantages and applications. While you can complete most jobs with a regular drill bit, there are occasions when a split point drill bit is the ideal option.

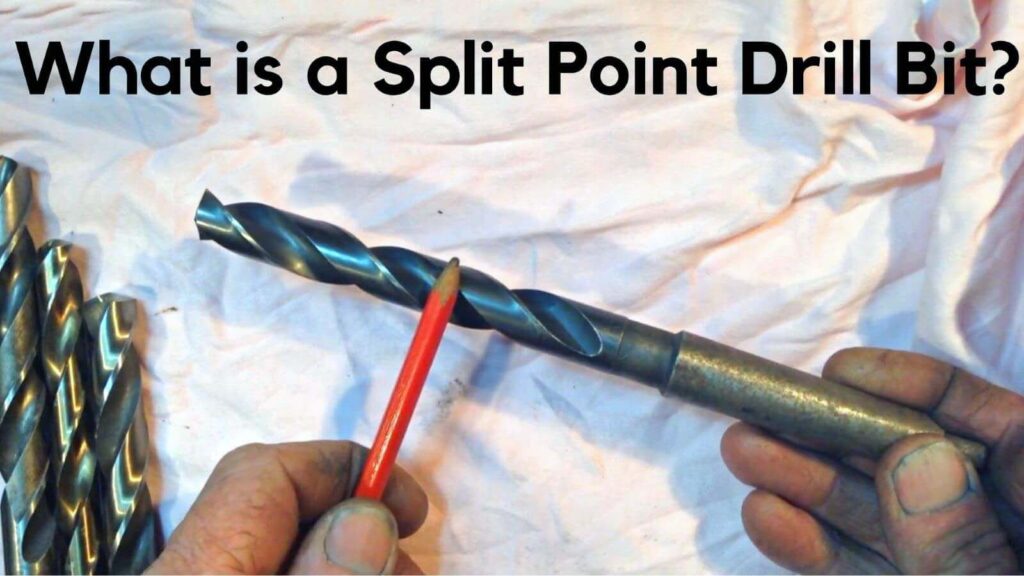

A split point drill bit is a high-speed bit type renowned for its precision and efficiency.

A split point drill bit contains more cutting edges than a regular drill bit, making it ideal for cutting hard materials such as metal.

T is one of the most often used quick action bits among DIY enthusiasts. When you look at the bit, the name says it all. It is split at the tip to relieve tension between the operator and the drill.

Table of Contents

What Is the Function of a Split Point Bit?

Spurs or flutes are used to describe the grooves on drill bits. These are intended to provide a destination for debris, thereby removing it from the project.

These grooves, or spurs, will protect the drill bit from snagging due to extra debris in the drilled hole.

Two of these spurs are included in a regular drill bit.

The drill bit’s tip is smooth and tapers away from the point at an angle of 118 or 135 degrees.

Due to the higher inclined tip, the 118-degree bits are perfect for drilling delicate materials.

Because the wider angle provides more pitch, the 135-degree bits are appropriate for drilling materials such as steel.

A more excellent pitch gives the bit’s tip additional strength, allowing it to drill through dense materials such as steel. Typically, the split point drill bit has a 135-degree angle tip. A split point drill bit’s shaft features three grooves or spurs. These spurs wrap around the entire bit, including the information.

Unlike ordinary drill bits, which end in a smooth point, split point drill bits contain grooves that extend beyond this point. As a result, the term “split point” was coined.

What Makes a Split Point Drill Bit Different?

Split point drill bits differ from standard drill bits in that they contain two cutting edges that chisel the material. The split point’s additional edges are carved into the chisel piece.

These additional grooves on the bit are intended to secure it in place, focusing the force and allowing for more effective cutting. Additionally, it takes less total pressure to cut.

The split point drill bit’s angle and four cutting edges give it an edge over regular drill bits in precision and force required.

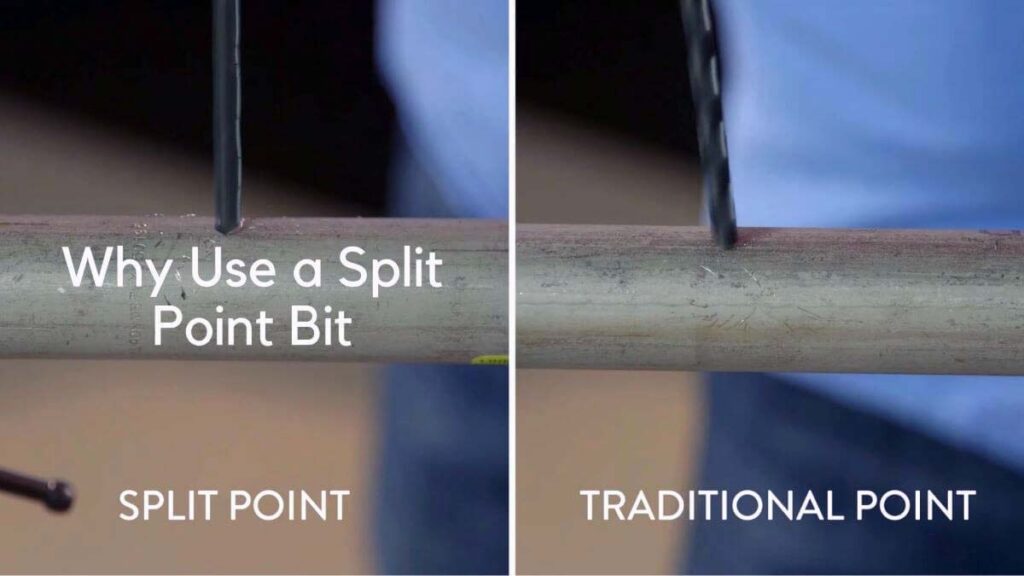

While drilling, other typical drill bits will move across the material. This is referred to as walking, and it has the potential to cause harm to the wood or metal on which you are working. These gouges or scratches formed by walking can be challenging to repair, so it’s best to avoid them.

The different edges in the center of a split point bit serve to secure the material and prevent it from walking. Drill bits with standard shanks act as a guide for your drill bit.

This is often accomplished by lightly striking an instrument into the material, such as a nail, to create a dent. This dent is referred to as a center punch, and it is designed to keep the drill bit from slipping and straying.

Split point drill bits are designed to address this issue, saving you time when creating a centre punch. It will speed up your job by eliminating the need to update the bit placement constantly.

A split point bit is an excellent choice for home drilling since it is rapid and precise.

Read More: How to Remove a Broken Drill Bit?

Why Use a Split Point Bit?

Split point drill bits have a higher resistance to heat than other drill bits.

Because drilling metal generates more excellent heat and friction, a split point drill is more durable for metal applications.

Additionally, the bit’s resilience to heat means that the grooves and tips do not become as quickly blunted. Typically, a split point drill bit is used to cut metals such as high alloy steels, stainless steels, and aluminium.

It can, however, be used on other surfaces as well, such as hardwood. Additionally, a split point bit works well on curved geometries, which are more prone to wander in conventional drill bits.

When working with rare hardwoods or metals, craftsmanship is critical. Use a split point drill bit.

As previously stated, the split point drill bit is intended to eliminate walking.

It is not capable of walking or gouging your material. It will produce clean holes due to the grooves that allow debris to be lifted from the material.

Read More: How to Use Left Hand Drill Bits

How Do You Locate A Split Point Bit?

Occasionally, split point drill bits are not sold as “split points.”Ensure that you examine the photographs or the actual item in the store. If it is a split-point drill bit, it will have a different face chipped into the smooth tip.

The grooves that run the length of the shaft will reach the tip. If the bit’s information is entirely smooth on all sides, it is not a split point. Select a split point drill bit made of steel or cobalt.

These materials are available in high-speed versions that are more resistant to the heat and friction generated by drilling metal.

Selecting the suitable drill bit material is critical for extending the tool’s life. Avoid heat-resistant materials such as titanium unless you intend to drill softer materials such as soft metals or wood.

Drill bit sizes are specified in terms of the shaft diameter. Drill bits are generally available in various sizes ranging from 1/16 inch to 12 inches. Numerous manufacturers offer custom sizes such as 7/64′′ or 3/32′′.

Split point drill bits are available at most hardware stores, including Lowe’s, Home Depot, and Ace Hardware. Additionally, they are available online through Amazon or directly from the maker.

A Split Point Drill Bit’s Restrictions

Split point drill bits come in a wide variety of sizes. Cannot use them on drills with a diameter greater than half an inch. As a result, they are best suited to jobs requiring smaller holes.

Additionally, they are difficult to sharpen due to the additional edges and facets on the tip.

The point is honed equally when sharpening a conventional drill bit with a smooth end.

On the other hand, a split point drill bit demands to maintain the 135-degree angle and polish each cutting edge. This complicates the process of honing split point drill bits.

Often, it is preferable to regrind these bits manually.

Split point drill bits, on the other hand, take longer to dull due to their significant substance and heat endurance. As a result, this may not be an issue for some time.

While this article concentrates on the traditional split point drill bit, a modified split point drill bit is also available. It has created a modified version to improve the standard performance by removing its limitations.

The modified split point bit is suitable for larger drills with a diameter of up to 3 inches.

Additionally, it requires less frequent sharpening.

Taking Care of and Maintaining the Split Point Drill Bit

Put your drill bits in a box to protect them from harm. Maintain a dry environment for your instruments to ensure that metal drill bits do not require a coating.

Sharpen your split point drill bit regularly rather than waiting until it becomes highly dull. Sharpening an incredibly fair bit will take a significant amount of time and energy compared to consistent tool upkeep.

The split point drill bit is an excellent investment if you care for your drill bits properly.

By securing the drill to the material, its unique construction prevents it from wandering.

A split point drill bit will save you time by drilling holes swiftly and correctly.

It is both heat resistant and robust, making it ideal for rigid materials such as metal.

(FAQs) about What is a Split Point Drill Bit

What are the prices of split point drill bits?

Split point drill bits typically cost between $2 and $6 per bit.

Can a drill press be used with a split-point drill bit?

Yes, you may use a split point drill bit on a drill press in addition to a hand drill. They are constructed to withstand pressure and perform admirably.

Additionally, they can utilize them in CNC drilling, which is frequently employed in mass production.

Is it possible to create a split point drill bit at home?

Specific individuals opt to grind their regular drill bits’ points to make a split point drill bit. While this is achievable, it necessitates precision and the use of precise angles. Given that split point drill bits cost between $2 and $6, purchasing one is suggested.

Can split point drill bits be used in hand drills?

Yes, split point bits can be used in both hand drills and drill presses.

Are split point bits more expensive than traditional bits?

Split point bits might be slightly more expensive due to their specialized design and benefits.

Do split point bits require special care during use?

While split point bits are designed for efficiency, standard drilling practices like using the appropriate speed and applying consistent pressure should be followed.

Can split point bits be resharpened?

Yes, split point bits can be resharpened like other drill bits. However, care should be taken to maintain their original geometry.

Are split point bits suitable for drilling large holes?

Split point bits are effective for drilling various hole sizes, but for very large holes, specialized bits might be more suitable.

Conclusion

A split point drill bit is a versatile tool that enhances accuracy, reduces wandering, and facilitates efficient drilling across various materials. Its innovative design and self-centering action make it a valuable asset in precision drilling tasks, providing cleaner holes and faster results.

Hey, I am Shihab Uddin, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.