Are you looking for a way to drill through rock efficiently? Look no further than SDS bits. These specially designed bits are engineered to handle rigid materials, including concrete, masonry, and rock.

But can an SDS bit be used to drill rock effectively? Yes, an SDS bit can be used to drill rock. An SDS bit is a specialized type of drill bit designed for rotary hammers and commonly used to drill into concrete and other hard materials.

However, it can also drill into rock, which is relatively easy and dense. When drilling into rock, it is essential to use the correct size and type of bit and the appropriate drilling technique.

This may involve using water or other lubricants to reduce heat and friction and choosing a suitable speed and pressure for the drill.

Following these guidelines makes it possible to successfully drill into rock using an SDS bit, making it a versatile tool for various construction and renovation projects.

Table of Contents

What is an SDS Bit?

An SDS bit is a drill bit with a shank design that allows it to be inserted into an SDS chuck. The SDS system was introduced in the 1970s by Bosch, and it quickly became the preferred method for drilling through hard materials.

The SDS system is known for its quick and easy bit changes, allowing users to switch between drill bits without needing additional tools. SDS bits come in various sizes and shapes, making them ideal for various drilling applications.

Check Also: 10 Best Drill Bit For Rock

Understanding The Basics Of Sds Bits

Sds (slotted drive system) bits are usually used in rotary hammers to drill dense materials like concrete, stone, or brick. The notch and spring-loaded ball in sds bits offer a secure, snug fit with the drill’s chuck to prevent slipping, making them ideal for drilling a range of materials.

There are three primary types of SDS bits: SDS-plus, SDS-max, and SDS-top, each designed for specific tasks. Sds bits function by converting the hammer’s energy into a drilling force that chips away at the material. The flutes facilitate material removal, while the carbide tips on the bit’s head ensure a straight and accurate drill hole.

How Do SDS Bits Work?

Here’s a breakdown of how SDS bits work:

- SDS Shank Design: SDS bits feature a unique design with two open grooves on either side. This design allows for quick and secure insertion into the SDS chuck of a compatible rotary hammer drill.

- Insertion and Locking: The SDS bit is inserted into the chuck by aligning the grooves with the corresponding slots in the drill. Once inserted, the bit is locked, ensuring a stable connection during drilling.

- Rotary Hammer Action: When the rotary hammer drill is activated, it combines rotational motion with a hammering action. The drill’s mechanism delivers rapid blows to the bit while it rotates, providing the force to penetrate rigid materials.

- Hammering and Anvil Effect: As the drill rotates and hammers, the bit moves slightly back and forth within the chuck. This movement is known as the hammering and anvil effect. It helps reduce the required force and enhances drilling efficiency.

- Breaking through Materials: The repeated hammering impacts from the drill bit gradually break through the material being drilled. The combination of rotational motion and hammering action allows SDS bits to penetrate harsh surfaces like concrete or masonry.

- Debris Removal: The drill’s rotational motion helps clear debris from the drilling area. This prevents clogging and ensures continuous drilling progress.

- Efficient Power Transfer: The SDS shank design maximizes power transfer from the drill to the bit. This efficient energy transmission enhances drilling performance and minimizes power loss during operation.

- Size and Types: SDS bits come in various sizes and types. The most common types are SDS-Plus and SDS-Max. SDS-Plus bits are suitable for holes up to 1 1/2 inches in diameter, while SDS-Max bits can handle larger holes up to 2 inches in diameter.

In summary, SDS bits utilize their specialized shank design to attach to SDS-compatible rotary hammer drills securely.

The drill’s combined rotational and hammering action enables the bit to break through rigid materials while efficiently clearing away debris. This design ensures effective drilling performance with reduced effort.

Read More: Will A Masonry Bit Drill Through Rock?

5 Factors to Consider When Using SDS Bits for Rock Drilling

When it comes to using SDS bits for rock drilling, several crucial factors must be considered. Considering these factors, you can ensure a successful and efficient drilling experience. Let’s delve into the key considerations:

- Type of Rock: The type of rock you’re drilling will significantly impact the effectiveness of SDS bits. Soft and porous rocks like sandstone and limestone are generally easier to drill through, while more complex and denser rocks such as granite and basalt require a more robust SDS bit.

- Bit Size: Selecting the appropriate bit size is essential. Larger rocks may necessitate more significant SDS bits to ensure optimal drilling performance. Using a bit that is too small might not deliver the desired results while using one that is too large can strain the bit and impede drilling progress.

- Speed and Pressure: Finding the right balance of rate and pressure is crucial for efficient rock drilling. Excessive pressure can lead to overheating and premature wear of the SDS bit, while insufficient pressure may hinder progress. Additionally, adjusting the drilling speed to match the hardness of the rock will help maintain control and precision.

- Cooling: As the drilling process generates heat, cooling the SDS bit becomes vital. Adequate cooling prevents overheating, prolongs the bit’s lifespan, and enhances drilling efficiency. Applying water or a cooling lubricant can effectively dissipate heat and prevent damage.

- Compatibility: Ensure that your SDS bit and drill are compatible. SDS drills are specifically designed to work with SDS bits, optimizing their performance and facilitating quick bit changes. Using an SDS bit with a standard drill may yield a different level of effectiveness.

By considering these factors and taking the necessary precautions, you can maximize the potential of your SDS bit and achieve successful rock drilling outcomes.

Now that I’ve explored the essential considerations, let’s delve into some valuable tips for drilling through rock using SDS bits. actors To Consider When Drilling Rock With Sds Bits

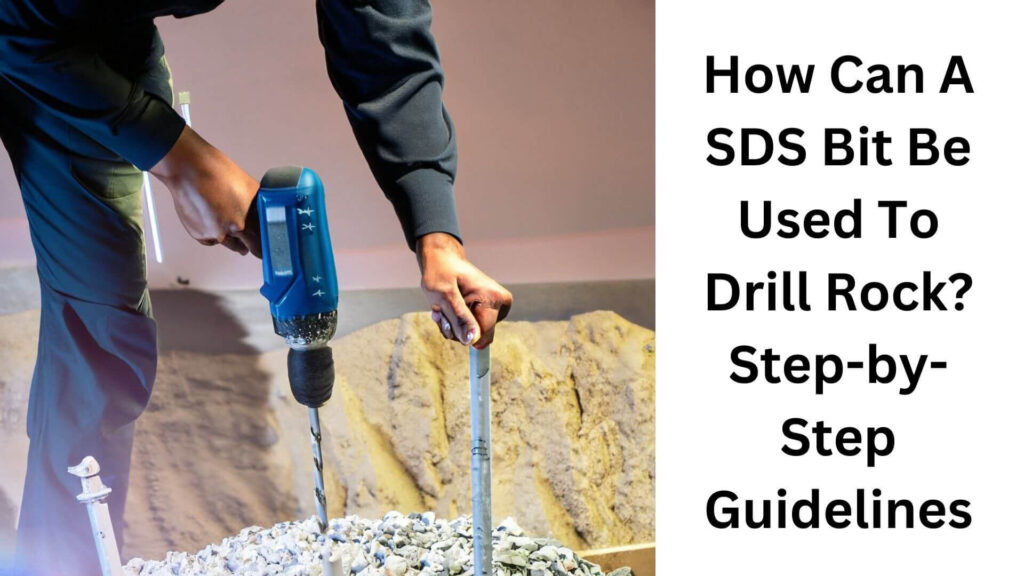

How Can A SDS Bit Be Used To Drill Rock? Step-by-Step Guidelines

Using an SDS bit to drill rock can be straightforward when following the proper steps. Here’s a step-by-step guideline to help you effectively utilize an SDS bit for rock drilling:

Step 1: Prepare the Work Area:

Begin by clearing the work area of any debris or obstacles that may hinder your drilling. Ensure a stable surface and remove any loose rocks or materials.

Step 2: Select the Appropriate SDS Bit:

Choose an SDS bit that matches the size and type of rock you’re drilling. Consider the hardness and density of the stone to determine the most suitable bit.

Step 3: Attach the SDS Bit to the Drill:

Insert the SDS bit into the SDS chuck of your drill. Ensure it is securely locked in place to prevent any accidents during drilling.

Step 4: Put on Safety Gear:

Prioritize your safety by wearing protective gear such as safety goggles, gloves, and a mask to shield yourself from flying debris and dust.

Step 5: Mark the Drilling Point:

Use a pencil or marker to mark the exact spot on the rock where you intend to drill. This will provide guidance and prevent any errors during the process.

Step 6: Position the Drill:

Hold the drill firmly, aligning the SDS bit with the marked drilling point on the rock. Maintain stability and balance throughout the drilling process.

Step 7: Apply Proper Pressure:

Apply consistent and moderate pressure on the drill as you start drilling into the rock. Avoid excessive force, which may cause the bit to overheat or break. Let the SDS bit do the work.

Step 8: Start the Drill:

Turn on the drill and slowly begin the drilling process. Ensure the drill is set to the appropriate speed for rock drilling. Maintain a steady and controlled motion as the bit penetrates the rock.

Step 9: Monitor the Progress:

Keep a close eye on the drilling progress. Observe the performance of the SDS bit and adjust the pressure and speed if necessary. Take breaks periodically to prevent overheating.

Step 10: Use Cooling Techniques:

To prevent the SDS bit from overheating, use cooling techniques during drilling. Apply water or a cooling lubricant to the drilling area to dissipate heat and extend the life of the bit.

Step 11: Clear Debris:

Periodically remove accumulated debris from the drilling area to maintain a clear path for the SDS bit. This will ensure optimal drilling efficiency and reduce the risk of the bit getting stuck.

Step 12: Complete the Drilling:

Continue drilling until you reach the desired depth or achieve your objective. Exercise caution and maintain control over the drill until you’ve completed the process.

Following these step-by-step guidelines, you can use an SDS bit to drill through rock effectively. Remember to prioritize safety, choose the right bit, and apply the proper techniques for successful rock drilling.

The Pros And Cons Of Using Sds Bits For Drilling Rock

Below is a table highlighting the pros and cons of using SDS bits for drilling rock:

| Pros | Cons |

| 1. High drilling efficiency | 1. Limited suitability for extremely hard or dense rock |

| 2. Quick and easy bit changes | 2. Potential risk of bit breakage with excessive force |

| 3. Reduced vibration and strain | 3. Requires an SDS-compatible drill |

| 4. Effective in drilling masonry | 4. It May produce more dust compared to other drilling methods |

| 5. Versatile for various applications | 5. Requires proper cooling to prevent overheating |

| 6. Provides faster drilling speed | 6. Larger SDS bits may require more power |

Alternative Options To Sds Bits For Drilling Rock

Drilling through rock is no easy feat, but are sds bits the only option? Not necessarily.

Diamond-tipped drill bits are a popular alternative for their durability and ability to withstand the most brutal rocks. Tungsten carbide drill bits are also a reliable option, known for their strength and precision.

Although not explicitly designed for rock, Masonry drill bits can still handle the job with proper use and pressure. Each option has its benefits, and choosing the right tool for the job is essential.

When drilling through rock, consider the type of rock, hardness, and thickness to determine the most effective tool for the task.

Read More: How To Sharpen Rock Drill Bits With Ease?

Frequently Asked Questions For Can A Sds Bit Be Used To Drill Rock?

What types of rock can SDS bits drill through?

SDS bits are designed to drill through hard and dense materials like concrete, masonry, brick, and some types of rock. However, the type of rock being drilled will determine the effectiveness of the SDS bit.

Can SDS bits drill through granite?

SDS bits can drill through granite, but it may require a more robust SDS bit than what is typically used for other materials.

How do I choose the right SDS bit for drilling through rock?

When choosing an SDS bit for drilling through rock, consider the type of rock being drilled, the size of the bit, and the speed and pressure needed.

Can I use a standard drill bit to drill through rock?

Standard drill bits may need to be more effective in drilling through rock. SDS bits are designed to handle complex and dense materials like concrete, masonry, brick, and some types of stone.

How do I prevent an SDS bit from overheating?

To prevent an SDS bit from overheating, use the correct speed and pressure, cool the bit regularly during the drilling process, and use a cooling lubricant.

Can I use an SDS drill to drill through rock?

Yes, an SDS drill can be used to drill through rock, but it’s essential to use the correct size SDS bit and follow the above-mentioned tips.

Final Summary

After analyzing all the factors, we have concluded that SDS bits are not the best fit for drilling rocks. Sds bits are specialized for drilling soft to medium materials like concrete, while stones require a more robust and complex penetrating tool.

Attempting to drill rocks with sds bits might cause damage to the bit or drill, leading to extra spending on replacements or repairs. Therefore, choosing the appropriate tools for drilling rocks is highly recommended.

Suppose you have various stones, including granite, sandstone and limestone; you might consider using carbide-tipped masonry drills or diamond drill bits, which have a more sturdy build and are explicitly designed to penetrate hard surfaces.

There are diverse methods and techniques for drilling rocks, and choosing the right tool will save you time and money. It is essential to know the tools’ capabilities and limitations and always use protective gear when handling power tools.

So, equip yourself with the proper knowledge to achieve a successful drilling experience.

Hey, I am Shihab Uddin, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.