An essential piece in a workshop toolkit is the SDS drill. It is convenient and nearly vital when it comes to drilling hard surfaces. SDS drills were initially manufactured in the mid-1970s.

Before the development of the SDS drill, it was exceedingly bulky and challenging for people to bore holes into concrete or similar surfaces.

Sometimes you need to drill into something hard. Whether drilling into a wooden board, a metal plate, or a concrete block, an SDS drill is the perfect tool.

With their ability to handle various drilling applications, SDS drills are essential to any construction or engineering team.

Table of Contents

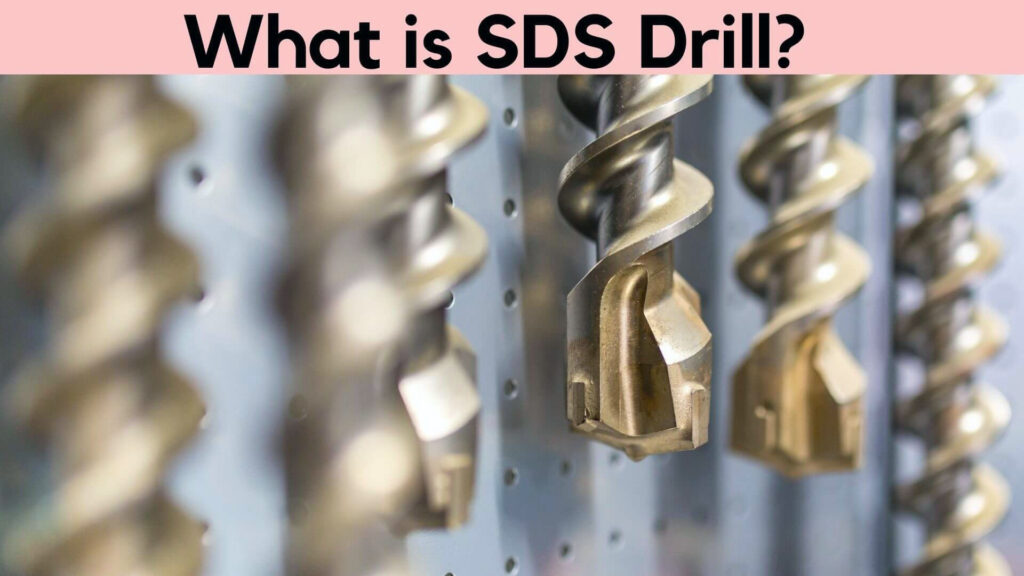

What is an SDS Drill?

An SDS drill is a drill that has a rotary action and a rotary with a hammer function. These features allow the drill to drill into hard surfaces quickly.

The SDS drill, whose name derives from the “Slotted Drive System” (others will state “Special Direct System”), introduced a novel method of operation.

Various causes have been credited with the success of the drill, but the rotary action and rotary with hammer function systems are likely the most impressive.

These characteristics allow SDS drills to penetrate wood, metal, concrete, and other hard materials. This explains why an SDS drill is considered an excellent concrete hammer drill.

Check Also: What is Mag Drill and How to Use it?

History of SDS Drill

It is practically hard to drill concrete or stone with a standard drill, but SDS drills and bits have shown to be the solution. After three decades of development in Germany, this innovative drilling style has been implemented in various fields.

Users were required to tighten the three jaws around the shank using ordinary drills and drill bits. The issue was that if the drill bit encountered any resistance, it would stall in the chuck and require retightening. Frequently aggravating and delaying work. Something required action.

A quick bit-changing system that was secure and allowed for some vertical movement was required in a rotary hammer drill. Where others had attempted to use spline bits in their development, Bosch delivered a dependable product.

This is where German brilliance comes into play by creating the first SDS bit. It will release SDS Plus and SDS Max in the future.

One of the most distinguishing characteristics between SDS and other varieties is how it fits in your power tool. Unlike conventional bits, typically held in place by three chuck jaws, an SDS bit contains slots that allow it to be connected and turned with precision and speed.

The original meaning of SDS, developed in the 1970s, was Stecken – Drehen – Sichern, which translates to “Insert – Twist – Secure” in English. The action is commonly performed when insetting a bit.

Read More: Can A Sds Bit Be Used To Drill Rock?

What are the Different Types of SDS Drills?

There are two different types of SDS drills –

- The Standard SDS Drill: The standard SDS drill is a bit more common and is used for smaller holes.

- The Rotary SDS Drill: The rotary SDS drill is better for larger holes because it has a faster speed and can go deeper.

Both drills are effective for drilling through rock, but the rotary SDS drill is better because it can Drill through more rigid materials.

When purchasing an SDS drill, get one appropriate for the job you plan on doing. Standard SDS drills are suitable for smaller tasks, while the rotary SDS drill is better suited for larger projects.

When it comes to drilling, several options are available, each with unique benefits. SDS drills can be categorized by their intended use: hole sawing, chiseling, and grinding.

- Hole sawing is a type of drilling used to cut through hard materials.

- Chiseling is a type of drilling used to shape or remove material from a surface.

- Grinding is a type of drilling that uses high-speed rotation to remove material by breaking it down into smaller pieces.

Each type of drill has its specific advantages and disadvantages.

For example, hole sawing is faster than other types of drilling but can lead to more significant damage if the blade slips.

Chiseling is less powerful but can be more accurate than other types of drilling.

Grinding is the most powerful and can remove large amounts of material quickly but may also leave behind debris.

Ultimately, deciding what drill to use depends on the task and the individual user’s preferences and capabilities.

What is the Difference Between the Standard SDS Drill and the Rotary SDS Drill?

The main difference between the standard SDS drill and the rotary SDS drill is the shape of the bit. The standard SDS drill has a regular bit, while the rotary SDS drill has a rotary bit.

The standard SDS drill is a rotary tool that uses a spinning bit to create holes in materials.

The rotary tool can be faster and easier to use than the standard SDS drill, but it also has limitations.

For example, the rotary SDS drill cannot create deep holes or remove large pieces of material.

The rotary SDS drill is also less effective when drilling through hard materials like concrete or metal.

The rotary SDS drill has a faster speed, larger chuck, and more torque than the standard SDS drill.

This Video is About Rotary SDS vs Impact Drills ->

What are the Other Features of the Rotary SDS Drill?

The other features of the rotary SDS drill include the following:

1. The rotary action and rotary with hammer function make it easy to drill into hard surfaces.

2. The presence of these features makes it a versatile drill.

3. The drill is easy to use and is perfect for drilling into hard surfaces

What are the Benefits of Using an SDS Drill?

The benefits of using an SDS drill include the following:

1. The rotary action and rotary with hammer function make it easy to drill into hard surfaces.

2. The presence of these features makes it a versatile drill.

3. The drill is easy to use and is perfect for drilling into hard surfaces.

4. The drill bit is easy to replace.

5. The drill bit is affordable.

Think About Safety

The quantity of energy an SDS drill system can deliver is another consideration that can influence the ultimate purchase decision.

The amount of power loaded in each SDS drill system is directly proportional to the damage that can be caused if the drill bit malfunctions and injures the operator.

Safety features include vibration, noise, drill speed, and clutch. Thus, safety and affordability are among the most apparent considerations when purchasing an SDS drill.

Aside from this, the optimum criterion for selecting an SDS drill is the nature of the task. Once this is determined, all that remains is carefully weighing the other considerations.

Check Also: How To Drill In Cast Iron Like a Pro

FAQS About What is SDS Drill?

What is the difference between hammer drills and SDS?

An SDS drill is a drill you can use with various drill bits. A hammer drill is a type of drill that is typically used for drilling into concrete.

What does the SDS on a drill stand for?

SDS stands for self-drilling screws.

Can a regular drill bit be used in an SDS drill?

No, you can not use a standard drill bit in an SDS drill. SDS (Semi-Automatic Drilling System) drill bits have a rugged casing designed to protect the drill bit from any object that may get in the way of the drilling process.

Can I use a carbide-tipped drill bit in an SDS drill?

No. it cannot use carbide-tipped drill bits in an SDS drill.

Final Word

SDS drills are essential for safe and efficient drilling operations in various environments. Make sure to know the different SDS drills available and their specific applications.

Hey, I am Shihab Uddin, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.