You must use a diamond-tipped drill bit and a steady hand to cut holes in granite with a drill bit. Here are some steps to follow: granite is a popular and durable material often used in kitchen countertops and flooring.

However, cutting or drilling through granite can be challenging. While various tools and methods are available for cutting granite, using a drill bit is an effective way to create holes in the granite.

It involves selecting the right drill bit, preparing the granite surface, and drilling the hole with precision and care.

In this article, I will guide you through cutting granite holes with a drill bit, enabling you to complete your diy projects easily.

Table of Contents

Properties Of Granite

Granite is a natural stone renowned for its durability, strength, and beauty. It is often used in homes and buildings as countertops, flooring, and walls. However, drilling holes in granite can be challenging, especially if you lack the knowledge and tools needed for the job.

Here I will delve into the properties of granite, including its composition and structure, factors that affect drilling effectiveness, and how to check the quality of granite for drilling.

1. Composition And Structure Of Granite

Granite is an igneous rock composed of three main minerals: feldspar, quartz, and mica. The ratio of these minerals varies, resulting in different granite types with varying colors, patterns, and textures. The unique beauty of granite is due to its mineral composition and how it was formed.

Granite is formed deep within the earth’s crust; over time, intense heat and pressure cause the minerals to align in a particular pattern. These patterns are what give granite its unique look.

2. Factors That Affect Drilling Effectiveness

Drilling through granite requires specialized equipment and techniques due to its hardness. Several factors can affect the effectiveness of drilling holes in granite, including:

- Drill bits: A high-quality diamond-tipped drill bit is essential for drilling through granite. These bits are much harder than traditional steel or carbide bits and can withstand the extreme pressure applied during drilling.

- Speed: Drilling too fast or too slow can cause problems during drilling. If you drill too fast, you can generate excessive heat that can damage the bit and the granite. On the other hand, drilling too slowly can cause the bit to wear out faster.

- Pressure: Applying the appropriate pressure during drilling is crucial. Too much pressure can cause the granite to crack or the bit to break. At the same time, too little pressure can prolong the drilling process unnecessarily.

3. How To Check The Quality Of Granite For Drilling

Before drilling into granite, it is important to ensure that the stone is of the right quality for the job. You can do this by considering the following factors:

- Color and pattern: High-quality granite typically has a uniform color and pattern. In contrast, lower-quality granite may have inconsistent colors and patterns.

- Absorption rate: Low-quality granite tends to be more porous and absorb liquids faster. You can test this by pouring a few drops of water onto the surface of the granite and timing how long it takes to absorb.

- Cracks and fissures: Inspect the granite for any visible cracks or fissures. These imperfections can weaken the stone and make it unsuitable for drilling.

Understanding the properties of granite is crucial to ensure productive and safe drilling. By considering various factors such as drill bits, speed, pressure, and granite quality, you can easily create holes in granite and achieve exceptional results.

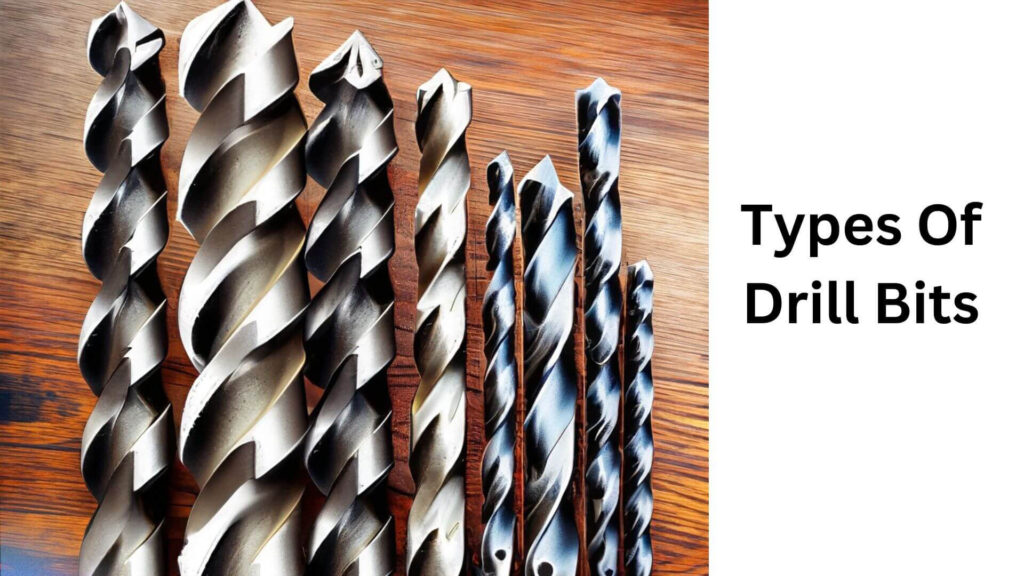

Types Of Drill Bits

1. Basic Design Of Drill Bit

Drill bits are mechanical tools that cut through hard substances such as granite. They are typically made of steel and come in many shapes and sizes. The basic design of a drill bit consists of a shank, body, and point.

The shank is the part that attaches to the drill, and the body is the part that cuts through the granite. The point helps guide the drill bit into the granite.

2. Materials Used For Drill Bit Construction

When drilling through granite, the type of drill bit material used is crucial to the project’s success. The most common materials used to manufacture drill bits for granite drilling are titanium, cobalt, and diamond. Each material has its strengths and weaknesses, with diamonds being the strongest and most effective at drilling through granite.

3. Types Of Drill Bits For Granite Drilling

Several types of drill bits are available for granite drilling, with varying degrees of efficiency. The most common drill bit types for granite drilling include:

- Straight shank drill bits: These are the most common and affordable drill bits available. They have a cylindrical shank and can be used in corded and cordless drills.

- Hex shank drill bits: These are similar to straight shank drill bits but with a hexagonal shank, making them more secure in the drill.

- Sds drill bits: These are high-performance drill bits for professional use. Their special shank design allows them to deliver more power, making them ideal for drilling through hard substances like granite.

4. Key Features Of Diamond-Coated Drill Bits

Diamond-coated drill bits are the most efficient and reliable drill bits for granite drilling. They are made of high-quality steel with a durable diamond coating that allows them to drill through granite easily. Some key features of diamond-coated drill bits include:

- Durability: Diamond-coated drill bits are highly durable, meaning they can last longer than other drill bits.

- Speed: These drill bits are faster than others, allowing you to finish your granite project more quickly.

- Precision: Diamond-coated drill bits offer more precision than others, allowing you to create accurate holes in your granite.

Drilling through granite requires using the right drill bit. By selecting the right type of drill bit, such as a diamond-coated drill bit, and having a basic understanding of its components and materials, you can successfully cut holes in granite.

Check Also: The 8 Best Drill Bit Options For Granite Projects

Planning The Project

How To Cut Granite Holes With Drill Bit: Planning The Project

To properly cut granite holes with a drill bit, there are several planning steps you need to take into consideration. Here are some key points:

1. Assessing The Necessary Tools And Materials

To cut a granite hole, you will need the following tools and materials:

- A diamond drill bit

- A power drill

- A template or guide for your hole placement

- A water source (a hose, bucket, or water pump)

- A clamp or vise to keep your granite in place

2. Determining The Hole Size And Placement

When cutting a hole in granite, it’s important to determine your hole’s size and placement carefully. Here’s how:

- Measure and mark your granite with a pencil to indicate where you want to drill your hole.

- Determine the diameter of the hole you need to drill.

- Make sure your template for hole placement aligns with your markings.

- Verify your measurements and markings before you begin drilling.

3. Blueprint For Drilling With Measurement

Now that you have your tools and materials and determined hole size and placement, it’s time to create a blueprint for drilling with measurement. Here are the key considerations:

- Carefully align your template or guide with your markings for the hole.

- Apply water to the area you plan to drill.

- Begin drilling slowly and carefully, following your template or guide.

- Pay attention to the drill’s speed, and take breaks to allow the granite to cool down and prevent the drill bit from overheating.

- Use a level to ensure your hole is straight, and measure to ensure you have achieved the desired depth.

Following these planning steps, you can successfully cut granite holes with a drill bit. Remember, proper planning is key to achieving the desired result, and it always pays to take your time and work carefully with your materials.

Read More: What Drill Bit To Use For Granite?

Setting Up Your Workspace

1. Securing The Granite Slab And Work Area

Before you begin cutting holes in the granite slab, securing both the slab and the work area is important to ensure precise cuts and prevent any accidents. Here’s what you need to do:

- Place the granite slab on a stable work surface that won’t move during drilling.

- Use clamps to secure the slab to the work surface.

- Mark the spot where you want to drill the hole with a pencil or pen.

- Cover the areas surrounding the drill spot with masking tape to reduce the chances of chipping or cracking around the drilling area.

2. Using Safety Equipment To Prevent Accidents

Granite is a tough material, and cutting holes in it can be daunting, especially if you are not handling the equipment correctly. It is always important to take proper safety precautions to prevent accidents. Here are some equipment you should consider:

- Safety goggles protect your eyes from granite dust.

- Earplugs protect your hearing from the loud noise of drilling.

- A dust mask to prevent inhalation of potentially harmful granite dust.

3. Proper Ventilation

Granite dust can be harmful if inhaled in large quantities. Ensuring proper ventilation in your workspace when drilling and cutting granite is important. Here are some ventilation tips to keep in mind:

- Open windows or doors to provide fresh air to the workspace.

- If your workspace has a ventilation system, switch it on before starting work.

- Wear a dust mask to prevent inhaling harmful granite dust.

By following these workspace setup guidelines, you’ll be ready to cut holes in granite with drill bits quickly. Take safety precautions, secure your workspace, and ensure proper ventilation. This will help you get precise cuts and ensure your safety while working with tough and durable granite surfaces.

Step 1- Marking The Holes

Steps To Measure And Mark The Holes

Cutting granite can be a challenging and time-consuming task. However, cutting granite holes can become much simpler with a drill bit and some simple steps.

The process begins with marking the holes that need to be drilled. Follow the steps below to measure and mark the holes accurately:

- Measure the size of the hole: Start by measuring the diameter of the hole that you need to drill in the granite using a measuring tape or ruler. Make sure you take accurate measurements to ensure the holes are the desired size.

- Determine the location: Determine the location of the hole on the granite slab and mark the location with a pencil. Use a level to ensure the location is straight, then mark the spot with an x.

- Secure the granite slab: Secure the granite slab to a stable workbench or table with clamps. This will prevent the slab from moving while drilling the holes.

- Apply masking tape: Apply masking tape to the area where the hole will be drilled. This will help prevent the drill bit from slipping or scratching the granite surface.

Considerations When Drilling Multiple Holes

If you are drilling multiple holes in a granite slab, it is essential to follow this consideration to ensure that the holes are accurately placed and of the desired size:

- Exact measurements: Take precise measurements and mark the hole locations with a pencil and level. Double-check the measurements before drilling to reduce mistakes.

- Step back: After drilling the first hole, verify that the position, diameter, and angle of the hole are as desired before drilling others.

- Let the drill bit cool down: When drilling multiple holes, let the drill bit cool down before drilling the next hole. This will prevent the drill bit from becoming overheated and will help prolong the life of the bit.

- Cover the granite: Cover the granite slab with a wet cloth between the drilling holes. This will prevent the granite from becoming too hot and cracking.

By adhering to these considerations, you’ll have precise and accurate holes designed in your granite slab.

With these simple yet essential tips, marking holes on your granite slab for drilling is stress-free. Once you have marked the locations, it’s time to learn how to drill granite holes using a drill bit. Stay tuned for the next step!

Step 2- Securing The Granite

When it comes to drilling holes into granite, securing the granite is a crucial step. Failure to stabilize the surface can cause the drill bit to slip, resulting in an unsatisfactory outcome. Here’s a step-by-step guide on how to secure granite for drilling.

Ensuring The Stability Of The Granite During Drilling

Before drilling into granite, it’s essential to ensure the surface is stable. Here are some ways to achieve this:

- Choose a stable surface: Granite slabs can be of varying thicknesses and sizes. To ensure stability, opt for a flat and stable surface that can bear the weight of the granite.

- Use a clamp: Clamping the granite in place can provide an added measure of stability. Secure the clamp to the surface and adjust it to fit the thickness of the stone.

- Mark and tape: Mark out the drilling points and cover the area to be drilled with masking tape. The tape offers added friction, keeping the granite in place.

How To Achieve A Firm Grip

A firm grip on the drill bit is essential to ensure precision drilling and to prevent the bit from slipping. Here are some ways to achieve a firm grip:

- Use dual-handle drills: Some drill models come with a handle on either side of the machine, ensuring a firm grip and greater control.

- Use a chuck key: Use a chuck key to tighten the drill bit into the chuck. A loose drill bit can compromise precision and, in some cases, cause harm.

- Use gloves: Handling the drill bit can be challenging, especially when installing it. Wearing gloves provides a better grip and prevents slipping.

Best Method For Drilling Into Hard Granite

Drilling into granite can be a time-consuming and challenging process. However, following the right techniques can make the process more manageable and efficient. Here are some tips for drilling into hard granite:

- Use diamond-tipped hole saws: Diamond-tipped saws are highly effective in drilling through hard stones like granite. These saws have diamond-coated tips that facilitate smoother and more precise drilling holes.

- Use water: Water is a crucial lubricant that helps to keep the drill bit cool and prevents it from overheating. You can use a spray bottle or run a constant stream of water while drilling.

- Take it slow: Drilling too fast can result in overheating the drill bit, thereby reducing its lifespan. Take it slow and steady, giving the drill bit time to cool down between drilling.

- Start with a small pilot hole: Starting with a small one helps guide the larger drill bit and prevent drift.

Using these techniques, you can create clean and precise holes in granite without damaging the surface. Happy drilling!

Step 3- Drilling The Granite

Proper Positioning Of The Drill Bit

To ensure precise granite drilling, it is vital to correctly position the drill bit. The following are the steps you need to follow:

- Place the tip of the drill bit on the granite surface and check if it is in a perpendicular position.

- Mark the granite’s spot to be drilled with a center punch tool.

- Align the drill bit with the center punch hole.

- Firmly secure the granite in place using clamps or a suction cup.

Maintaining The Right Speed

Drilling granite smoothly without causing damage to the drill bit requires maintaining the right speed. Follow the tips below to maintain an optimal drilling speed:

- Slowly increase the drill speed until you find a suitable rate.

- Ensure the speed remains consistent throughout the drilling process.

- Avoid forcing the drill bit too hard on the granite as this can cause unnecessary damage.

How To Avoid Overheating The Drill Bit

Overheating of the drill bit typically occurs when drilling granite, leading to worn-out bits or safety hazards. Here’s how to avoid overheating the drill bit:

- Use a diamond-tipped drill bit specifically designed for granite.

- Constantly add water or a suitable lubricant to cool down the drill bit, reduce friction and remove debris.

- Avoid using too much pressure, as this overheats the drill bit.

By following these simple guidelines, you can successfully drill precise holes in granite without causing damage to the drill bit. Proper positioning, maintaining the right speed, and preventing overheating are essential steps that require attention.

Finishing The Project

Cutting granite holes with a drill bit can be challenging, requiring skill, patience, and knowledge of the right tools and techniques. In the last section, we covered the steps involved in the actual cutting process. In this section, we will focus on finishing the project by clearing debris, removing sharp edges, and cleaning the surface of the granite.

1. Clearing Debris

Once you have completed drilling the holes, cleaning up any debris or dust left behind is essential. Here’s how you can do it:

- Use a vacuum cleaner to suck up any loose dust and debris.

- Wipe the surface of the granite with a damp cloth to remove any remaining residue.

- Make sure to dispose of the debris safely and appropriately.

2. Removing Any Sharp Edges

Drilling granite can cause sharp edges that must be removed for safety and aesthetics. Here’s how to do it:

- Use a diamond hand pad to file down any rough or sharp edges.

- Smooth out the edges using 100-grit sandpaper.

- Move on to 200-grit and 400-grit sandpapers to achieve a polished finish.

3. Cleaning The Surface Of The Granite

Finally, it’s time to clean your newly drilled granite surface thoroughly. Here are the steps to follow:

- Mix warm water and mild detergent in a bucket.

- Dip a soft cloth into the mixture and wring out excess water.

- Gently wipe the surface of the granite with the cloth, making sure to remove any dirt or grime.

- Rinse the cloth in clean water and repeat until the surface is clean.

- Dry the surface using a clean, dry cloth.

- After cleaning the surface, you may want to apply a granite sealer to protect it from stains and spills.

Congratulations! You have successfully completed your granite drilling project. You achieve a professional-looking finish by following these steps and using the right tools and techniques. Remember to proceed with caution and always prioritize safety when drilling granite.

Frequently Asked Questions Of How To Cut Granite Holes With Drill Bit

Can I Cut Granite With A Drill Bit?

You can cut granite with a drill bit, using the right technique and tools.

What Type Of Drill Bit Should I Use For Granite?

You should use a diamond-tipped drill bit for cutting granite, as they’re the most effective.

How Do I Prepare The Granite For Drilling?

To prepare the granite for drilling, mark the hole’s position and use a center punch to make a small indentation.

What Is The Best Way To Cut A Hole In Granite?

The best way to cut a hole in granite is to use a diamond-tipped drill bit attached to an angle grinder.

How Do I Avoid Damaging The Granite While Drilling?

To avoid damaging the granite, use a steady hand, use water to cool the bit, and drill slowly and carefully.

Final Word

Cutting granite holes with a drill bit might seem daunting at first, but it is an achievable task with the right tools and techniques. Remember to invest in a high-quality diamond drill bit, use water as a lubricant, maintain consistent speed and pressure, and take safety precautions seriously.

With these tips, you can achieve precise and smooth cuts in granite surfaces without hiring a professional. Cutting your granite holes can also save you time and money on home improvement projects. Don’t be afraid to try it out and see the impressive results!

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.