Attention DIY enthusiasts and woodworking aficionados! Are you looking to take your drilling capabilities to the next level? If you’re ready to unlock a world of precision and stability in your projects, it’s time to learn how to install a vice to a floor drill press.

The answer is: To install a vice to a floor drill press, first, identify the correct size of the vice and drill press table. Align the vice with the center of the table, secure the vice to the table with clamps, and drill holes into the table as per the vice’s mounting system.

The vice is a vital tool to hold and secure materials during drilling operations, making it an essential addition to a drill press.

In this article, I will discuss installing a vice to a floor drill press, the necessary tools and materials, safety precautions, and other helpful tips to ensure a successful installation. So let’s get started!

Table of Contents

Step 1: Preparing For Installation

Explanation Of Safety Precautions That Need To Be Taken Before Beginning Installation

Before installing a vice to your floor drill press, it is essential to consider several safety precautions.

- It is advisable to wear proper personal protective equipment (PPE) such as safety goggles, gloves, and a dust mask to avoid any injury or inhalation of dust or metal chips that may be produced during installation.

- Before installing, ensure the drill press is grounded correctly to avoid any electric shock hazards.

- Ensure that the drill press is switched off and unplugged from the power source, as it may cause injury or damage to the drill press if it is done otherwise.

- Keep in mind the weight of the vice. As metal is a heavy material, it is essential to consider how to lift the vice and avoid any back injuries during installation.

Cleaning The Work Surface Of The Drill Press

Before starting the installation process, it is essential to clean the work surface of the drill press.

- Remove any dirt or debris from the drill press using a brush or damp cloth to ensure a clean surface for installation.

- A clean, flat surface will ensure that the vice is appropriately attached to the drill press so no oil or grease is present on the work surface.

Gathering Necessary Tools And Equipment For The Installation Process

While installing a vice to a floor drill press, ensuring you have all the necessary tools and equipment is essential.

- A suitable vice that can be attached to the drill press.

- Screws or bolts attach the vice to the drill press.

- A wrench or socket is set to tighten the screws/bolts.

- A drill bit to drill through the vice if necessary.

- A drill bit to make a hole in the work surface if required.

- A pencil or marker to mark the spots where you need to drill the holes.

- A level to ensure that the drill press is in a level position before installation.

Keeping all these tools and equipment handy will ensure a smooth installation process. With these necessary tools and safety precautions, you’ll be well on your way to successfully installing a vice to your floor drill press in no time, making your woodworking projects more precise and effortless.

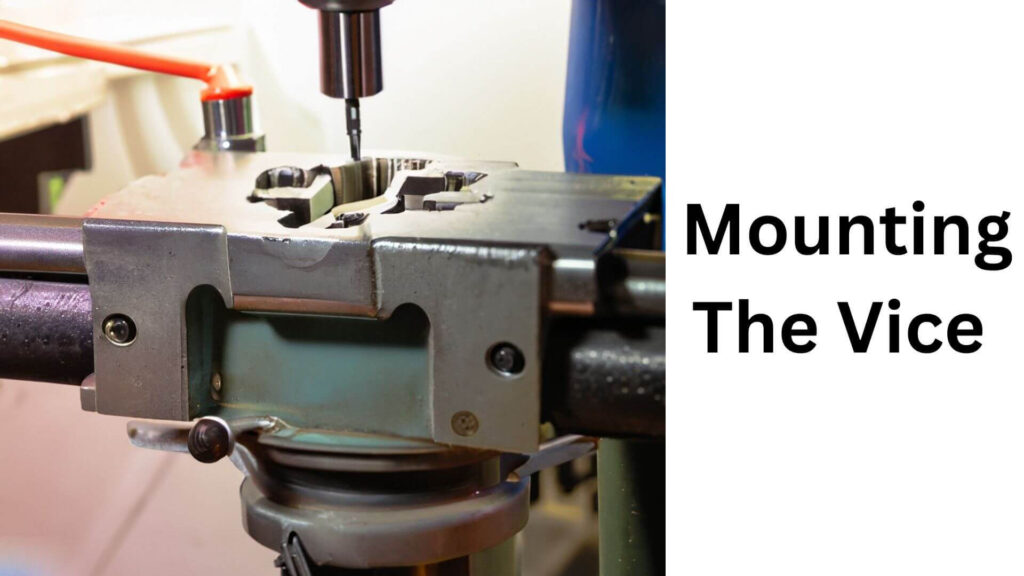

Step 2: Mounting The Vice

Installing a vice to a floor drill press is an essential skill every DIY enthusiast or professional needs to learn. In this post, we will guide you through the process. In the previous section, we learned about the tools and materials needed for the job.

Now, you will move on to step 2: mounting the vice.

Explanation Of The Different Types Of Vices That Are Available For A Floor Drill Press

Before you dive into the nitty-gritty of mounting a vice to a floor drill press, let’s first discuss the different types of vices available.

- Bench vice: A bench vice is a type of vice that is clamped to a workbench. It is the most common type of vice and usually comes in different sizes.

- Drill press vice: A drill press vice is designed to work with a drill press. It is mounted to the drill press table and securely holds the material to be drilled.

- Cross-slide vice: A cross-slide vice is a type of vice mounted on a slide that moves in two directions. It is designed for precision drilling, milling, and boring operations.

Choosing The Right Type Of Vice For The Job

When choosing a vice for your floor drill press, consider the following factors:

- The material and size of the workpiece: If you are working on a small or delicate material, a bench vice may suffice. However, a drill press or cross-slide vice may be more suitable for working on larger or heavier materials.

- The type of drilling operation: For precision drilling, milling, or boring operations, a cross-slide vice may be necessary. A drill press vice can handle most drilling operations, while a bench vice may need to be expanded for complex projects.

- The capacity of the drill press: Check the maximum opening of the vice and ensure it’s compatible with the power of your drill press.

Using The Mounting Hardware To Attach The Vice To The Drill Press Table

Once you have the correct type of vice, it’s time to mount it to the drill press table.

- Align the vice on the desired spot on the drill press table. Ensure that it’s securely positioned and leveled on the table surface.

- Using the vice’s mounting holes as a guide, mark the drill holes on the drill press table.

- Remove the vice and drill the holes in the marked spots. Use the recommended drill bit size for the mounting screws.

- Align the vice with the newly drilled holes and fasten the mounting screws.

- Double-check the vice’s alignment and stability before using it.

Following these steps, you can successfully mount a vice to your floor drill press. Just remember to choose the right type of vice for the task and use the appropriate mounting hardware. Happy drilling!

Check Also: Top Floor Standing Drill Press for Home and Workshop Use

Step 3: Adjusting The Vice

Knowing how to install a vice is essential if you work with a floor drill press. In the previous steps, you have learned how to prepare the drill press and mount the vice onto it. Now, you will dive into adjusting the vice to fit the workpiece and aligning it to the drill bit.

Explanation Of How To Adjust The Vice To Fit The Workpiece

The vice must fit securely around the workpiece to prevent it from moving during drilling.

- Loosen the vice jaw and position it to fit the workpiece.

- Tighten the vice jaw until it is snug around the workpiece.

- Check if the workpiece is secure by attempting to move it around. If it wobbles, adjust the vice and try again.

- Once you have confirmed that the workpiece is secured, tighten the vice as much as possible.

Discussing How To Align The Vice For The Drill Bit Properly

Proper alignment of the vice and the drill bit is crucial because it ensures accuracy in drilling.

- Hold the drill bit to the workpiece to determine where the hole should be drilled.

- Adjust the vice to position the workpiece underneath where the drill bit will go through.

- Use the quill handle to lower the drill bit towards the workpiece.

- Check that the drill bit is aligned with where it should go on the workpiece.

- Adjust the vice as necessary to achieve the proper positioning.

Tips On Ensuring The Vice Is Tight And Secure Before Drilling

Before drilling, it is essential to ensure the vice is tight and secure.

- Turn the handle of the vice to tighten it firmly around the workpiece.

- Check that the workpiece and vice do not move around. If it wobbles, adjust the vice accordingly.

- Consider using clamps to secure the vice for extra stability.

- Always double-check that the vice is tight and secure before drilling.

Practice these steps several times until you are comfortable adjusting and aligning the vice quickly. Before you know it, it will become second nature!

Read More: How to Mount a Floor Drill Press?

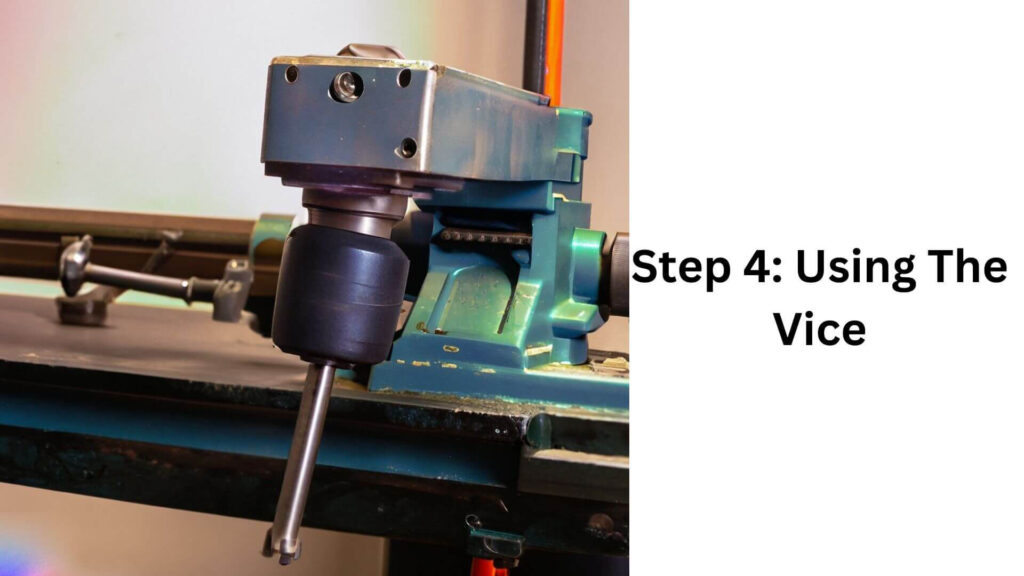

Step 4: Using The Vice

Explanation Of How To Use A Vice With A Floor Drill Press

Using a vice with your floor drill press is a crucial part of drilling holes accurately. Before you start drilling, make sure that the vice is installed correctly and in good condition. Once established, you can steady your workpiece, ensuring it does not move while you drill.

- Open the jaws of the vice by turning the handle anti-clockwise.

- Place your workpiece between the jaws of the vice.

- Adjust the jaws until they grip the workpiece snugly but not too tightly. You want to hold the workpiece firmly but not so tight that you damage it.

- Once your workpiece is securely in place, you can begin drilling.

Discussion Of The Importance Of Clamping The Workpiece Properly

Clamping your workpiece correctly is crucial for drilling straight holes. When a workpiece moves even a little bit during drilling, it can affect the accuracy of the whole project.

- Ensure your vice is in good condition and securely attached to the drill press.

- Place the workpiece between the vice’s jaws and adjust until it is snug.

- Check to ensure the workpiece is level and square with the drill press table. Use a court to check for accuracy.

- Clamp the workpiece in multiple locations to prevent it from moving while drilling.

- Always use light to moderate pressure when clamping so you don’t damage the workpiece.

Read More: How to Convert Floor Drill Press in Benchtop?

Tips On Drilling Straight Holes With The Help Of The Vice

Using a vice with your floor drill press can help you drill straight and accurate holes.

- Always use a drill bit appropriate for the hole you need to drill.

- Use a drill bit that is sharp and in good condition.

- Keep your workpiece firmly clamped in the vice to prevent it from moving during drilling.

- Place a small piece of scrap wood between the workpiece and the jaws of the vice to prevent damage to your workpiece.

- To ensure you drill straight holes, use the guide on your drill press or a drill press fence to align your workpiece with the drill bit.

- Start drilling slowly, and apply light pressure. This will help you keep the drill bit straight and prevent it from wandering.

- Pull the drill bit out frequently to remove the wood debris and prevent overheating if you need to drill a deep hole.

- Lastly, remember to wear safety glasses and keep your hands away from the drill bit while drilling.

By following these tips, you can ensure that you make accurate and straight holes with your floor drill press and vice.

Frequently Asked Questions: How To Install A Vice To A Floor Drill Press?

How Do I Install A Vice To A Floor Drill Press?

To install a vice to a floor drill press, you must secure the vice to the drill press table, align it and tighten the bolts.

What Type Of Vice Is Suitable For A Floor Drill Press?

A heavy-duty, durable vice with a firm grip is the best for a floor drill press.

What Safety Precautions Should I Take When Installing A Vice?

Wear safety goggles and gloves, secure the drill press, ensure the vice is aligned, and avoid loose clothing.

How Do I Maintain My Vice After Installation?

Clean the vice regularly with a clean cloth, lubricate the moving parts, and store them in a safe and dry place.

Can I Use A Floor Drill Press Vice For Other Applications?

Yes, depending on the type of vice you have installed, you can use it for various drilling and milling applications.

Final Opinion

After following the steps outlined in this guide, you should better understand how to install a vice to a floor drill press. It may seem daunting, especially for those unfamiliar with the equipment, but it can be accomplished relatively easily with the right tools and patience.

Remember always to follow safety guidelines when working with power tools and to double-check that everything is securely fastened before use. A vice installed on your floor drill press can make many woodworking tasks much easier and more efficient. With this newfound knowledge, you’ll be able to take on more projects with confidence and precision. Happy drilling!

Hey, I am Shihab Uddin, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.