A vice is an essential tool for securely holding a workpiece during drilling operations. Installing a vice on your floor drill press not only increases safety but also ensures more precise and efficient drilling. Whether you’re a professional or a DIY enthusiast, learning how to install and use a vice with your floor drill press can elevate the quality of your work.

This blog will walk you through the entire process, from preparing your tools to mounting, adjusting, and using the vice effectively.

Table of Contents

Step 1: Preparing For Installation

Before you start mounting a vice on your floor drill press, it’s important to prepare properly. This step will ensure a smooth installation process and reduce the risk of errors or safety issues.

Explanation Of Safety Precautions That Need To Be Taken Before Beginning Installation

Safety should always be your top priority when working with heavy equipment like a drill press. Here are some safety precautions to follow:

- Wear Personal Protective Equipment (PPE): Always wear safety goggles, gloves, and protective footwear. This will protect you from flying debris, accidental tool slips, and foot injuries from heavy objects.

- Unplug the Drill Press: Disconnect the machine from the power source to prevent any accidental activation during installation.

- Use the Right Tools: Ensure that all tools you are using for installation are in good condition and suitable for the job. Faulty tools can lead to mistakes or injuries.

- Organize Your Workspace: Keep your workspace clean and clutter-free to avoid tripping over tools or materials. A tidy workspace allows you to focus on the installation without distractions.

Cleaning the Work Surface of the Drill Press

Before mounting the vice, clean the work surface of your drill press thoroughly. Over time, dust, metal shavings, and oil can accumulate on the surface. These contaminants can affect the performance of the vice and prevent it from gripping properly.

- Use a Brush or Air Compressor: Clear any loose debris from the surface using a brush or an air compressor.

- Wipe Down the Surface: Use a rag or cloth with some degreaser or mild detergent to clean any grease or oil residue on the drill press table.

- Dry the Surface: Ensure the surface is completely dry before installing the vice. Moisture can cause rust or reduce the grip of the vice.

Gathering Necessary Tools and Equipment for the Installation Process

To install a vice on your floor drill press, you’ll need the right tools and materials. Here’s a list of what you’ll need:

- Vice: Choose a vice that fits your drill press and the type of work you’ll be doing.

- Mounting Hardware: Most vices come with bolts or clamps for securing them to the drill press table. If not, ensure you have appropriately sized bolts, washers, and nuts.

- Wrench or Socket Set: You’ll need a wrench or socket set to tighten the bolts and secure the vice in place.

- Measuring Tools: A tape measure or ruler will help ensure the vice is positioned properly.

- Spirit Level: To ensure your vice is level and properly aligned with the drill bit.

Once you have all the necessary tools and materials ready, you can proceed with mounting the vice.

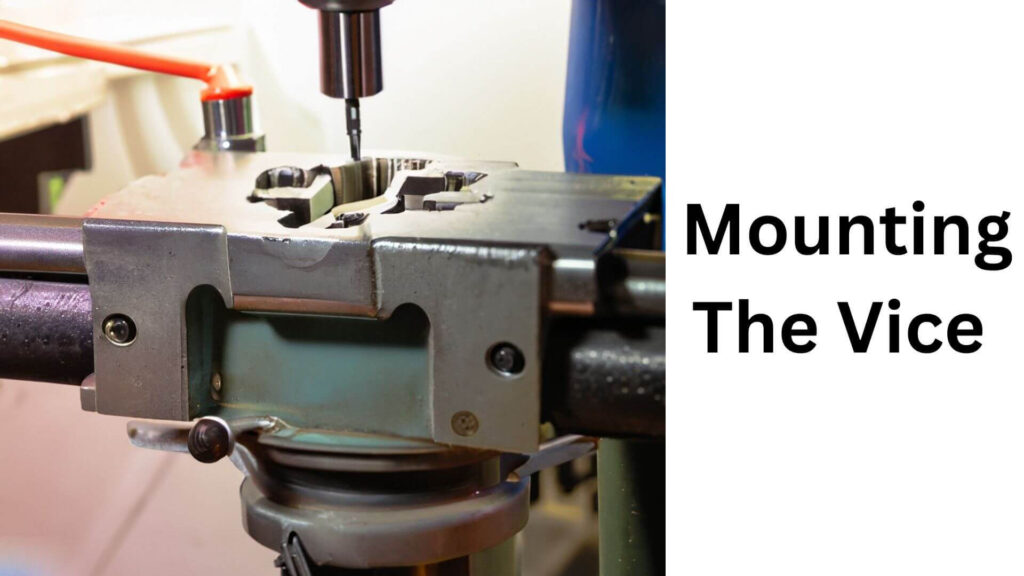

Step 2: Mounting The Vice

Mounting the vice correctly is crucial for ensuring stable and accurate drilling. Follow these steps to mount the vice on your floor drill press table securely.

Explanation of the Different Types of Vices That Are Available for a Floor Drill Press

There are various types of vices available for a drill press, and the right choice depends on the kind of work you plan to do. Here are the most common types:

- Standard Drill Press Vice: This is the most basic type of vice, designed to hold small and medium-sized workpieces securely in place.

- Cross Slide Vice: A more advanced vice, the cross slide allows for precise movement in both the X and Y axes. It’s ideal for applications that require exact positioning, such as metalworking.

- Angle Vice: This vice can be adjusted to hold the workpiece at various angles, making it great for projects that involve angled drilling.

- Tilting Vice: Similar to an angle vice, but allows for more freedom in tilting the workpiece, making it suitable for more complex tasks.

Choosing the Right Type of Vice for the Job

When selecting a vice for your floor drill press, consider the following factors:

- Size of the Workpiece: Ensure the jaws of the vice are large enough to hold the workpieces you commonly work with.

- Type of Material: If you work with metal or hard materials, choose a heavy-duty vice with a strong clamping force.

- Precision Requirements: If you need precise control over positioning, a cross slide vice is recommended.

Using the Mounting Hardware to Attach the Vice to the Drill Press Table

Once you’ve selected the right vice, it’s time to mount it:

Tighten the Bolts: Use a wrench or socket set to tighten the bolts securely. Ensure that the vice is firmly attached and does not move.

Position the Vice: Place the vice on the drill press table, ensuring it is aligned with the drill bit. Center the vice under the drill chuck for optimal accuracy.

Mark the Mounting Holes: Use a pencil or marker to outline the mounting holes of the vice on the drill press table.

Drill the Mounting Holes: If your drill press table does not have pre-drilled holes, use a drill to create holes for the bolts.

Insert the Bolts: Place the bolts through the holes in the vice and drill press table. Make sure to use washers to distribute the load and prevent the bolts from loosening.

Check Also: Top Floor Standing Drill Press for Home and Workshop Use

Step 3: Adjusting The Vice

After the vice is mounted, you’ll need to adjust it to fit the workpiece and ensure alignment with the drill bit.

Explanation of How to Adjust the Vice to Fit the Workpiece

To adjust the vice for your workpiece:

- Open the Jaws: Turn the handle or crank of the vice to open the jaws wide enough to fit the workpiece.

- Insert the Workpiece: Place the workpiece between the jaws of the vice, ensuring it is positioned correctly.

- Tighten the Vice: Turn the handle to tighten the jaws around the workpiece. Make sure the workpiece is held securely but avoid overtightening, as this could damage the material.

Discussing How to Align the Vice for the Drill Bit Properly

Proper alignment between the vice and the drill bit is crucial for accurate drilling. Here’s how to ensure perfect alignment:

- Lower the Drill Bit: Using the handwheel, lower the drill bit toward the workpiece without turning on the drill press. This will allow you to check the alignment.

- Adjust the Vice Position: If the drill bit is not centered over the spot where you want to drill, loosen the bolts slightly and adjust the position of the vice.

- Tighten the Bolts Again: Once the vice is aligned, tighten the bolts to secure it in place.

- Check for Level: Use a spirit level to ensure that the vice and workpiece are level. An uneven surface could lead to inaccurate drilling.

Tips on Ensuring the Vice is Tight and Secure Before Drilling

To prevent any movement of the vice or workpiece during drilling:

Avoid Over-tightening: While the vice should be secure, avoid overtightening the bolts, which could strip the threads or damage the table.

Double-check the Clamping: Ensure the vice is clamped tightly to the drill press table and that the workpiece is securely held between the jaws.

Test for Movement: Give the vice a slight shake to check if it is stable. If there is any movement, re-tighten the bolts or clamps.

Read More: How to Mount a Floor Drill Press?

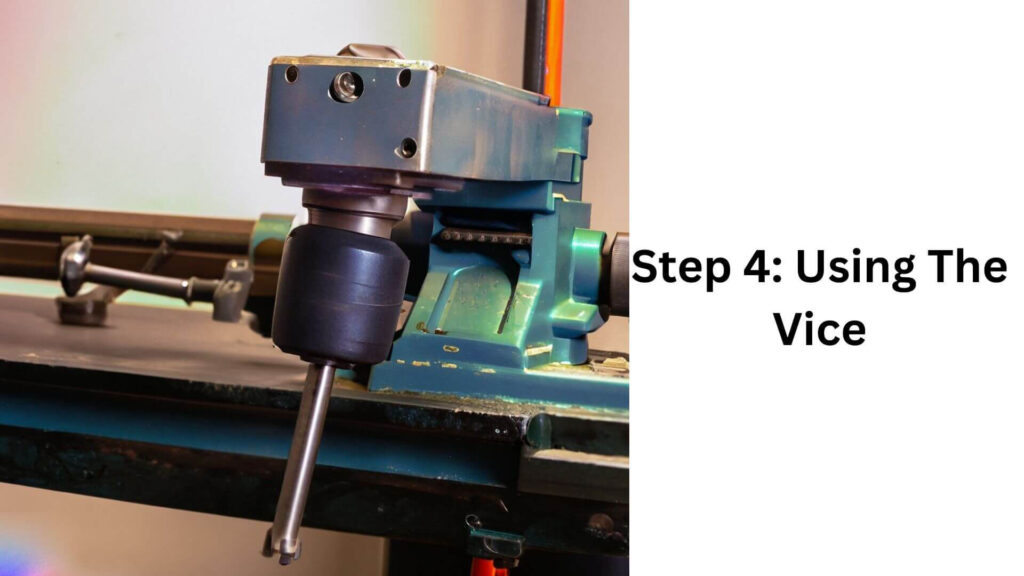

Step 4: Using The Vice

Now that your vice is installed and adjusted, you’re ready to use it. Follow these steps for effective drilling.

Explanation of How to Use a Vice with a Floor Drill Press

Using a vice with a floor drill press ensures stability and precision during drilling operations. Here’s a quick overview:

- Insert the Workpiece: Position your material in the jaws of the vice, making sure it is centered and aligned with the drill bit.

- Clamp the Workpiece Securely: Tighten the vice to hold the workpiece in place. Ensure there is no movement in the workpiece before you start drilling.

- Lower the Drill Bit: Use the handwheel to lower the drill bit slowly toward the workpiece, aligning it with the drilling mark.

- Start Drilling: Turn on the drill press and gently lower the drill bit into the material. Avoid applying too much pressure, as this could cause the workpiece to shift or damage the drill bit.

Discussion of the Importance of Clamping the Workpiece Properly

Properly clamping the workpiece in the vice is crucial for safe and accurate drilling. A loose workpiece can shift during drilling, leading to inaccurate holes or even accidents. Always double-check the clamping before turning on the drill press.

Tips on Drilling Straight Holes with the Help of the Vice

Here are some tips to ensure straight and accurate holes:

Check the Drill Speed: Adjust the speed of your drill press depending on the material you’re working with. Harder materials require slower speeds, while softer materials can be drilled at higher speeds.

Use a Pilot Hole: For larger holes, start by drilling a small pilot hole to guide the larger drill bit.

Apply Steady Pressure: Avoid forcing the drill bit through the material. Use steady, even pressure to ensure a clean cut.

Frequently Asked Questions: How To Install A Vice To A Floor Drill Press?

How do I choose the right vice for my floor drill press?

Choose a vice that suits the size of your workpiece and the type of material you’re working with. For precision tasks, a cross slide vice may be the best option.

Can I install a vice without drilling new holes in my drill press table?

Some drill press tables come with pre-drilled holes. If your table doesn’t, you will need to drill holes to mount the vice securely.

How do I keep my vice from moving during use?

Ensure the vice is bolted tightly to the drill press table and the workpiece is clamped securely. If movement persists, check the condition of the bolts and mounting hardware.

How often should I check the alignment of my vice?

It’s a good idea to check the alignment every time you install a new workpiece, as even slight shifts can affect the accuracy of your drilling.

Final Opinion

Installing a vice on your floor drill press is a relatively simple task that can greatly improve the quality of your drilling operations. By following the steps outlined in this guide—preparing for installation, mounting the vice, adjusting it for your workpiece, and using it properly—you’ll ensure a safer, more accurate drilling experience. Proper alignment, secure clamping, and choosing the right type of vice for your tasks are key to achieving the best results.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.