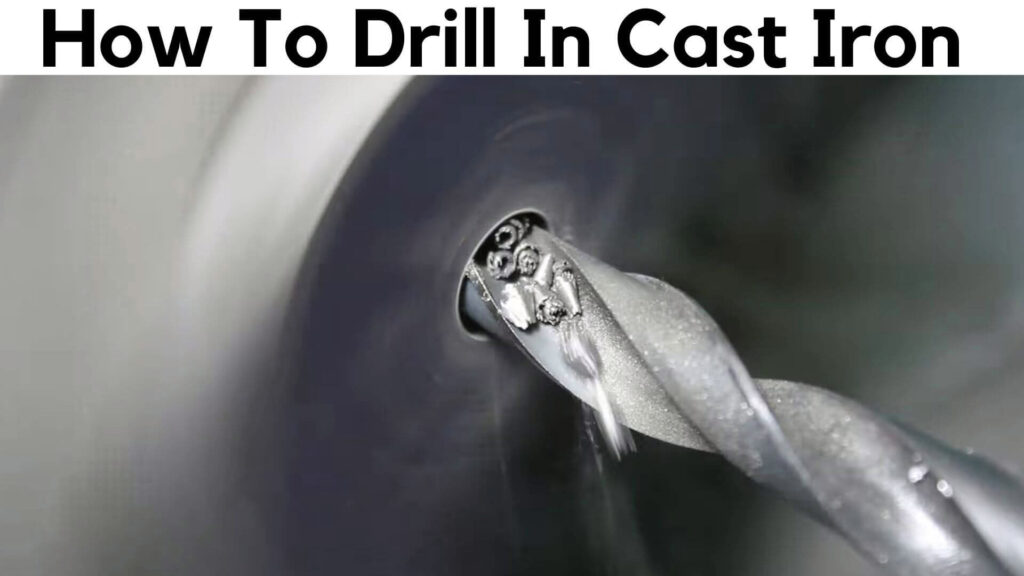

Drilling into cast iron may seem like a daunting task due to its hardness and brittle nature, but with the right tools and techniques, it can be done efficiently and safely. Whether you’re working on a cast iron bathtub, sink, or pot, this ultimate guide will walk you through the process, step by step, helping you understand the best tools to use and how to drill without damaging the material. By the end, you’ll have a solid grasp of how to approach drilling in cast iron like a pro.

Table of Contents

Is it Possible to Drill Into Cast Iron?

Yes, it’s absolutely possible to drill into cast iron, but it requires special care. Cast iron is a hard, brittle material, making it susceptible to cracking or fracturing if not handled properly. The key to successful drilling lies in using the right drill bit, lubricating the surface to minimize friction and heat, and applying slow, consistent pressure. When done correctly, drilling into cast iron is safe and effective for a wide range of projects, from adding fixtures to altering plumbing or modifying cookware.

What Tools Are Required To Drill Cast Iron?

Drilling into cast iron isn’t just about grabbing any drill and bit. Specific tools are required to ensure that the process is smooth and the cast iron remains intact. Here’s what you’ll need:

- Drill: A powerful corded or cordless drill with adjustable speed control. Corded drills tend to be more powerful and are often recommended for tougher materials like cast iron.

- Drill bits: You’ll need drill bits designed for metal, such as high-speed steel (HSS) bits, carbide bits, or spiral bits. More on choosing the right bit below.

- Cutting fluid or lubricant: Lubricating the bit and cast iron will reduce friction, prevent heat buildup, and protect your bit from wearing down prematurely.

- Center punch: A center punch creates a small indentation in the cast iron to guide the drill bit and prevent it from wandering.

- Clamps: Secure the cast iron in place to ensure stability during drilling.

- Protective gear: Always wear safety goggles, gloves, and a dust mask to protect yourself from metal shavings.

Check Also: The Right Size Drill Bit For 1/2″ Concrete Anchors?

How Do I Drill Into Cast Iron?

Drilling into cast iron involves several key steps that must be followed to ensure a clean, successful hole. Here’s a breakdown of how to approach the process:

- Mark the spot: Identify where you want to drill and use a marker or chalk to clearly indicate the drilling point.

- Create an indentation: Use a center punch and a hammer to create a small dimple at the marked spot. This helps guide the drill bit and prevents it from slipping.

- Select the correct drill bit: Choose a metal drill bit suitable for cast iron, such as HSS, carbide, or cobalt.

- Apply cutting fluid: Apply lubricant or cutting fluid to the surface of the cast iron and the drill bit to minimize heat and friction.

- Drill at a low speed: Start your drill at a low speed, and slowly work your way into the cast iron. Avoid applying too much pressure.

- Pause to cool the bit: Periodically stop drilling to allow the bit to cool and reapply cutting fluid as needed.

- Finish the hole: Once you’ve drilled through the cast iron, clean the hole and remove any debris.

How to Drill a Hole in Cast Iron with a Metal Drill Bit

Drilling a hole in cast iron using a metal drill bit (HSS or cobalt) is a straightforward process, provided you follow these steps:

Finish the hole: Once the hole is complete, carefully remove the bit and clean the area.

Mark the spot: Use a marker and center punch to define where you’ll drill.

Lubricate the area: Apply cutting fluid to both the drill bit and the cast iron surface.

Start drilling slowly: Set the drill to a low speed and gently push the bit into the cast iron.

Cool the bit: Pause periodically to cool the bit and reapply cutting fluid.

Check Also: can you drill through carbon fibre

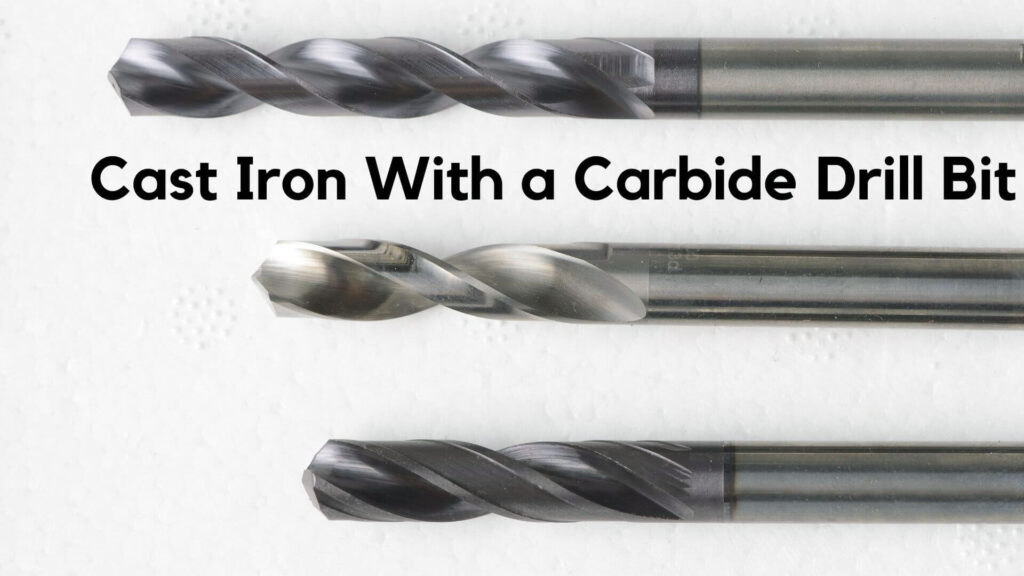

How to Drill a Hole in Cast Iron with a Carbide Drill Bit

Carbide drill bits are known for their durability and ability to withstand high heat, making them perfect for tougher drilling jobs. Here’s how to drill with a carbide bit:

Monitor temperature: Carbide can tolerate heat, but overheating can still damage the material or bit.

Set up your drill: Attach the carbide bit and ensure it’s tightly secured.

Mark and center punch the hole: As always, mark the spot and create an indentation with the center punch.

Apply cutting fluid: This will help reduce heat and extend the life of your carbide bit.

Drill at a moderate speed: Carbide bits can handle higher speeds than HSS bits, but it’s still essential to go slow to avoid damaging the cast iron.

How to Drill a Hole in Cast Iron with a Spiral Drill Bit

Spiral drill bits are particularly effective when working with thick cast iron because they efficiently remove debris. Here’s the process:

Finish gradually: Once the final bit size is reached, drill slowly to ensure a clean, even hole.

Choose the right size: Pick a spiral bit that matches your desired hole size.

Drill in increments: It’s often easier to start with a smaller hole and gradually enlarge it using larger bits.

Keep the bit lubricated: Cutting fluid is still essential, even with a spiral bit, to prevent overheating and ensure smooth drilling.

Check Also: how to drill through metal studs

How to Drill a Hole in Cast Iron Without Ruining It

To drill a hole in cast iron without causing damage, follow these guidelines:

- Use the right drill bit: Always use a drill bit designed for metal, like HSS, carbide, or cobalt.

- Keep the bit cool: Continuously apply cutting fluid or water to the drill bit and surface to prevent overheating.

- Drill at low speed: Rushing through the job can lead to cracking or other damage to the cast iron.

- Avoid excessive pressure: Let the drill bit do the work—applying too much force can fracture the cast iron.

How to Drill a Hole in Cast Iron Bathtub?

Drilling into a cast iron bathtub requires extra care, as you’re dealing with a thick, enamel-coated surface. Here’s how to do it:

- Choose a carbide or HSS bit: These bits can handle the thickness of a bathtub.

- Mark the spot: Use a marker and center punch to guide your drilling.

- Start with a small pilot hole: Begin with a smaller drill bit before working up to the final size.

- Apply cutting fluid: Keep the bit cool with cutting fluid, as drilling through thick cast iron generates significant heat.

- Go slow and steady: Use a low drill speed to prevent cracking the enamel or cast iron.

How to Drill a Hole in Cast Iron Sink?

Drilling into a cast iron sink follows a similar process to a bathtub:

- Select a carbide-tipped or HSS bit: These bits are durable enough for the job.

- Mark and punch the spot: Create a small guide hole with a center punch.

- Drill slowly: Keep the drill at a low speed to avoid damaging the sink’s enamel and cast iron.

- Apply cutting fluid: Always lubricate to prevent overheating.

How to Drill a Hole in Cast Iron Pot?

If you are drilling into an empty cast iron pot, start by outlining the desired hole with a pencil or pen. Once you have made your outline, use your measurements to choose your drill bit from those listed above for drilling in castiron baths, sinks, and pots.

When drilling into empty pots or pans, it is essential not to overheat your drill bit or apply too much pressure; otherwise, you could damage the pot or pan.

What are the Benefits of Drilling into Cast Iron?

Drilling into cast iron is a complicated process. It requires a lot of time and patience. However, it can be gratifying and beneficial if done correctly.

Drilling into cast iron offers several benefits:

- Customization: You can modify cast iron items for specific needs, such as creating drain holes in sinks or pots.

- Versatility: Drilling allows you to add fixtures, create bolt holes, or make modifications to cast iron objects.

- Durability: Once a hole is drilled, cast iron retains its strength and remains a durable material.

What are the Risks of Drilling into Cast Iron?

Drilling into cast iron comes with a few risks:

- Cracking: Cast iron is brittle, and too much pressure or speed can cause it to crack or shatter.

- Tool damage: Using the wrong bit or not using lubrication can quickly dull or damage your drill bits.

- Heat buildup: Drilling too quickly can generate excess heat, which may warp or weaken the cast iron.

Helpful Hints and Advice

Go slow: Always drill at a slow speed to prevent overheating and cracking.

Lubricate: Cutting fluid or water should be used throughout the process to keep the bit cool.

Use the right tools: Ensure you’re using the correct drill bits for the job, preferably HSS, carbide, or cobalt bits.

When you use a drill bit on any metal, keep an old rag nearby. You’ll have to clean up the metal shavings and any extra cutting fluid. As many DIYers have done, sharp pieces can hurt you if you wipe them on your pants or shirt.

Always use a permanent marker to mark your surface first. This indicator will show you exactly where you want to start drilling instead of leaving you to guess.

Don’t forget to check how wide the thing you are drilling into is! If you go too far, you might hurt whatever is behind it. It would help if you always had a ruler and a leveler in your tool kit to avoid these problems.

Lastly, never drill into loose cast iron. If it’s not already attached to something, it has to have vices.

FAQs About How To Drill In Cast Iron

What is a good drill bit for drilling into cast iron?

The best drill bits for drilling into cast iron are:

Cobalt Bits: Extremely tough and heat-resistant, ideal for longer drilling tasks.

HSS (High-Speed Steel): A reliable, general-purpose option for metal drilling.

Carbide-Tipped Bits: More durable and better for high-temperature applications.

What type of drill bit should you use to drill into cast iron?

For cast iron, you should use HSS, carbide-tipped, or cobalt drill bits. These are strong enough to penetrate the material without dulling or breaking.

How deep should you drill into cast iron?

The depth of the hole depends on your specific project. For most applications, you should drill only as deep as necessary to accommodate your screws or bolts.

How do you know when to stop drilling in cast iron?

You should stop drilling once the bit has passed through the cast iron. If you’re drilling a partial hole, stop as soon as you reach the desired depth. Use a depth gauge or a marker on your drill bit to ensure accuracy.

Last Word

Drilling into cast iron can be tricky, but with the right tools, techniques, and patience, you can achieve professional results. Always remember to use appropriate drill bits, go slowly, and lubricate throughout the process to protect your tools and the cast iron material. Whether you’re working on a bathtub, sink, or pot, following these steps will help you drill into cast iron like a pro.

Here are a few essential things to remember from this post:

- you can drill cast iron with any drill bit for metal.

- If you are drilling many holes, don’t forget to use cutting fluid.

- When drilling into any surface, you should always use a clamp or vice.

- You should wear safety glasses, gloves, and clothing.

- Remember to use a marker, a center punch, and a hammer to mark the spot.

- Start slowly to avoid making too much friction, heat, and wear.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.