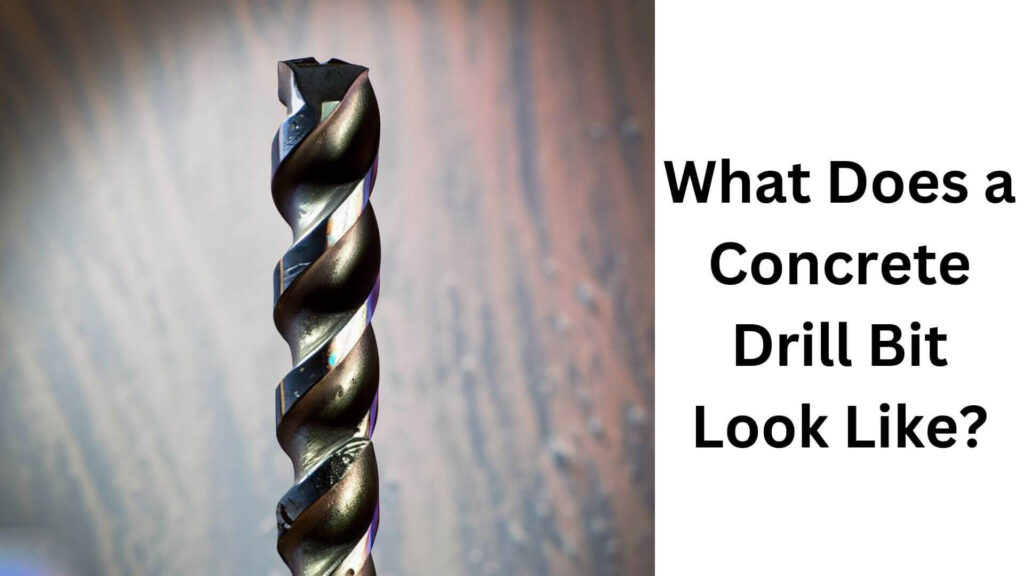

Have you ever wondered what a concrete drill bit looks like? If you’re embarking on a DIY project that involves drilling into concrete, understanding the anatomy of a concrete drill bit is crucial.

A concrete drill bit is typically black and made of carbide or diamond material. It has a threaded shank for attachment to a drill.

Concrete drill bits, or masonry drill bits, are designed to tackle the most challenging materials easily. These specialized bits boast a distinct appearance, featuring a sturdy shaft with flutes or grooves along its length.

Concrete drill bits come in various shapes and sizes but share some standard features. So, join me in this exploration to understand what a substantial drill bit looks like, enabling you to choose the perfect tool for your next project.

Table of Contents

Anatomy Of A Concrete Drill Bit

Concrete drill bits are essential tools for construction workers and DIY enthusiasts alike. Proper drilling tools ensure safety and efficiency when drilling into concrete.

I will take a closer look at the anatomy of a concrete drill bit, the major parts that make up this powerful tool, and how each element affects its performance.

Major Parts Of A Concrete Drill Bit

The primary components of a concrete drill bit are the shank, body, and tip. Each part plays a vital role in drilling through harsh concrete surfaces.

- Shank: The shank is the drill bit part that fits into the drill chuck. A good shank design ensures the drill bit stays in place during drilling, preventing slips or wobbling. A hexagonal shank is generally the best option, offering the most stability.

- Body: The body of the drill bit is the part that extends from the shank to the tip. It is responsible for guiding the bit through the concrete and managing the drilling process’s speed. The body of the drill bit should be made of high-quality steel to ensure durability when drilling through harsh surfaces.

- Tip: The tip of the drill bit is the most crucial part. It is responsible for making contact with the surface and drilling through. The information should be made of a rigid material, commonly tungsten carbide. Shape and diameter vary depending on the project type.

Read More: What Color is a Concrete Drill Bit?

How Each Part Affects The Performance Of The Concrete Drill Bit

The design and quality of each part directly affect the drill bit’s performance when drilling into concrete.

- Shank: A high-quality shank design ensures the drill bit stays in place during drilling. This is essential because if the drill bit shakes, it can create holes larger than needed or shift and damage the surface. The hexagonal shank is the best for stability and keeping the bit in place.

- Body: The body guides the drill bit through the concrete, controls the drilling speed, and removes debris from the hole.

A well-crafted body is essential to ensure smooth and efficient drilling. The use of high-quality steel adds durability to the drill bit.

- Tip: The tip is the most essential part of the drill bit. It directly contacts the surface, and its shape determines the hole drilled’s size and shape.

The best material for the tip is tungsten carbide due to its hardness and durability. The diameter and shape vary based on the project requirements.

Concrete drill bits come in different shapes and sizes for different project needs. Choosing the right drill bit for the job is essential to ensure efficient and safe drilling.

By understanding the anatomy of a concrete drill bit and how each part affects its performance, you’ll be better equipped to choose the perfect drill bit for your job.

Read More: What Size Drill Bit for 3/8 Concrete Anchor?

Common Materials Used In Concrete Drill Bits

Concrete is a complex, dense material that can be tricky to penetrate. This is where a concrete drill bit comes in handy.

Concrete drill bits are specialized tools designed to enable drilling through concrete more efficiently. We’ll look at some common materials used in tangible drill bits.

Read More: Can a Titanium Drill Bits Go Through Concrete Walls?

Types Of Metals And Alloys Commonly Used For Drill Bits

When it comes to concrete drill bits, there are a few different types of metals and alloys commonly used, each with advantages and disadvantages.

High-Speed Steel (Hss)

- They are made from an alloy of steel, tungsten, and other metals.

- Inexpensive and widely available.

- Performs well on softer concrete.

- It tends to wear out quickly when used on more rigid concrete.

Cobalt

- A type of hss that is more durable and heat-resistant.

- Performs better than hss on more rigid concrete.

- More expensive than hss.

Carbide-Tipped

- It is made from a steel body with a carbide tip.

- Carbide is a challenging but brittle material.

- Performs well on all types of concrete, including reinforced concrete.

- More expensive than hss and Cobalt.

Diamond-Tipped

- The most durable and expensive type of concrete drill bit.

- The diamond coating can cut through virtually any concrete, including reinforced concrete.

- Suitable for heavy-duty applications.

Read More: Step-by-Step Guide on Removing a Broken Drill Bit from Concrete Walls

Advantages And Disadvantages Of Each Material

Each type of material used in concrete drill bits has strengths and weaknesses.

High-Speed Steel (Hss)

Advantages

- Inexpensive

- Widely available

- Performs well on softer concrete

Disadvantages

- Wears out quickly on harder concrete

Cobalt

Advantages

- More durable and heat-resistant than hss

- Performs better on more rigid concrete than hss

Disadvantages

- More expensive than hss

Carbide-Tipped

Advantages

- Performs well on all types of concrete, including reinforced concrete

- More durable than hss and cobalt

Disadvantages

- More expensive than hss and cobalt

Diamond-Tipped

Advantages

- It can cut through virtually any type of concrete, including reinforced concrete

- Suitable for heavy-duty applications

Disadvantages

- Very expensive

Choosing the right material for your concrete drill bit depends on the specific application and the type of concrete you’ll be drilling through.

While hss and cobalt are sufficient for most applications, carbide-tipped or diamond-tipped drill bits are recommended to drill through hard or reinforced concrete.

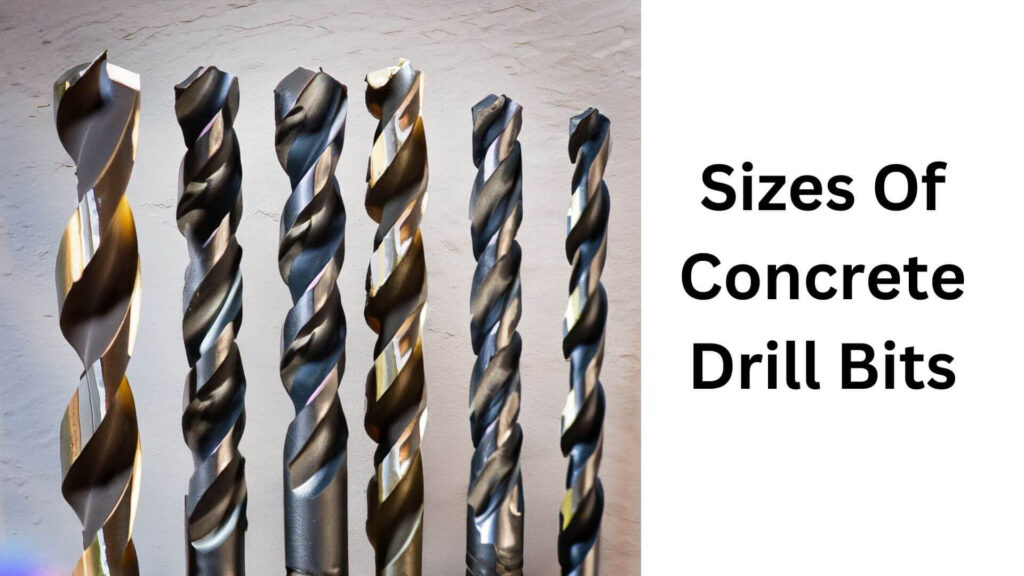

Sizes Of Concrete Drill Bits

Overview Of The Most Common Sizes Of Concrete Drill Bits

Concrete drill bits come in various sizes to suit different drilling needs.

- 3/16 inch, 1/4 inch, and 5/16 inch: These sizes are ideal for drilling small holes in concrete walls or floors. They are commonly used for hanging pictures or installing light fixtures.

- 3/8 inch and 1/2 inch: These sizes are suitable for drilling larger holes in concrete walls or floors. They are commonly used for installing anchors or bolts.

- 5/8 inch, 3/4 inch, and 1 inch: These sizes are perfect for drilling holes in concrete slabs or blocks. They are commonly used for installing pipes or electrical conduits.

The Importance Of Choosing The Right Size For The Job

Choosing the right size of the concrete drill bit is essential to ensure you achieve the desired results.

- If you use a drill bit that is too small for the job, you may not be able to drill the hole to the required depth or diameter.

- If you use a drill bit that is too large for the job, you may damage the wall or floor, or the hole may be too big for the anchor or bolt you are trying to install.

- Using the correct size of the drill bit will also make the job easier and quicker, as the drill bit will be more effective at drilling through the concrete.

Remember, it’s always better to choose a slightly larger drill bit than a smaller one when in doubt. This will give you some wiggle room if you need to adjust the hole size slightly.

Choosing the right size of the concrete drill bit is crucial to ensure that your drilling job is successful and efficient.

Check Also: 8 Best Drill Bit for Concrete

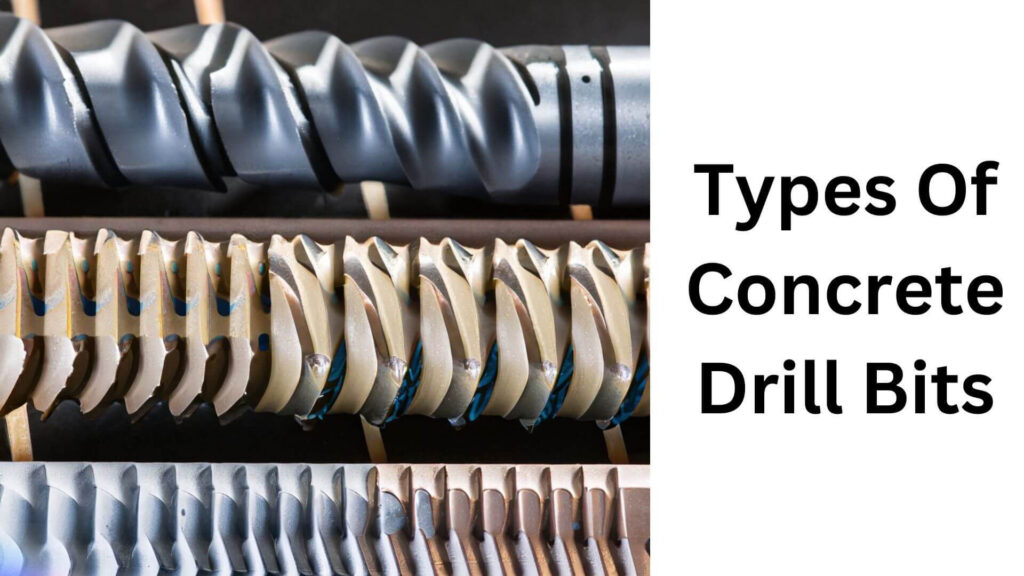

Types Of Concrete Drill Bits

Different Types Of Concrete Drill Bits

Having the right drill bit for the job is crucial when drilling into concrete. Having the right drill bit will make the drilling process smoother and increase the lifespan of your drill. Several types of concrete drill bits are available, each designed for specific drilling purposes.

Here are the three main types of concrete drill bits.

- Masonry drill bits: These are the most commonly used drill bits for concrete and masonry. They have a carbide tip that helps penetrate the concrete quickly. They come in different sizes, depending on the hole diameter needed.

- Diamond drill bits: These are used for drilling more complex surfaces like tiles, stone, and concrete. They have diamond-embedded tips that give them an edge over traditional masonry drill bits. These drill bits are perfect for creating precise holes without damaging the surface.

- Hammer drill bits: These are designed for electric hammer drills and operate with rotation and percussion. They have a chiselled tip that helps to break through tough materials like concrete and stone. The hammer drill bits come in different sizes and are suitable for heavy-duty drilling tasks.

When To Use Each Type Of Drill Bit

Using the correct type of drill bit for the job is essential to ensure you get the best results. Below is a list of the situations where you should use each drill bit.

- Masonry drill bits are ideal for drilling into standard concrete blocks, bricks, and soft stones. If you need to create holes for anchors, fasteners, or wall plugs, the masonry drill bits are the best option.

- Diamond drill bits: Use a diamond drill bit when drilling into more complex materials like granite, marble, and porcelain tiles. These drill bits make holes in delicate surfaces where accuracy is crucial.

- Hammer drill bits: If you need to drill large holes in concrete or other rigid materials, use hammer drill bits. They are ideal for professionals who work in the construction industry and need to dig through heavy-duty materials regularly.

Selecting the correct drill bit for the job will ensure that the drilling process is smooth and the results are excellent. Masonry, diamond, and hammer drill bits are three popular types of concrete drill bits with unique features and functions.

Remember to choose the drill bit that fits your drilling needs and the surface you’re drilling into.

Read More: Best Drill For Concrete Walls!

Frequently Asked Questions Of What Does A Concrete Drill Bit Look Like?

What Is A Concrete Drill Bit?

A concrete drill bit is a specialised tool for drilling into concrete surfaces.

What Are The Parts Of A Concrete Drill Bit?

The parts of a concrete drill bit include the shank, body, and tip.

What Types Of Tips Are Available For Concrete Drill Bits?

The most common types of concrete drill bit tips are carbide and diamond.

What Is The Diameter Range Of A Concrete Drill Bit?

The diameter range of a concrete drill bit usually starts from 1/8 inch and goes up to 1 inch or more.

How Do I Choose The Right Concrete Drill Bit For My Project?

Choose a concrete drill bit based on the diameter of the hole you need, the type of material you are drilling into, and the power of your drill.

Last Word

A concrete drill bit is essential for anyone working in the construction industry to drill through rigid materials like concrete, brick, and limestone.

It is easily distinguishable from other drill bits by its unique design, which features a sharp conical tip and stiff, wide-body flutes that help evacuate dust and debris as it drills through tough and dense surfaces.

While choosing the right drill bit for concrete drilling, it is crucial to consider the thickness and density of the material you are working with and the power and speed of your drill.

Investing in high-quality concrete drill bits can help increase efficiency, reduce the risk of drill bit failure and damage, and ultimately save time and money.

With the proper knowledge and tools, you can drill through concrete like a pro and create the precise holes you need for your project.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.