Carbon fiber is one of the most durable and lightweight materials used across a variety of industries, from aerospace to automotive. Its incredible strength-to-weight ratio makes it ideal for high-performance applications. However, drilling into carbon fiber can be a tricky task. If not done correctly, it can result in cracks, fraying, or damaging the integrity of the material.

In this step-by-step guide, we’ll walk you through the process of drilling carbon fiber efficiently and safely. We’ll also cover the best tools, techniques, and tips to avoid mistakes and get the best results.

Table of Contents

What is Carbon Fiber?

Carbon fiber is a composite material made up of carbon atoms arranged in long, thin fibers. These fibers are woven together and typically embedded in a resin to form a sheet or part. This material is popular because it is five times stronger than steel and significantly lighter, making it ideal for industries like automotive, aerospace, and sporting goods. Despite its strength, carbon fiber can be delicate during machining, which is why it requires specialized techniques for drilling.

What are the Best Tools For Drilling Carbon Fiber?

Here are the Best Tools For Drilling Carbon Fiber :

- Makita 18V drill

- Dewalt DCS790C2 drill

- Bosch PS50C drill

- Milwaukee M18 drill

- DeWalt 18V Max drill

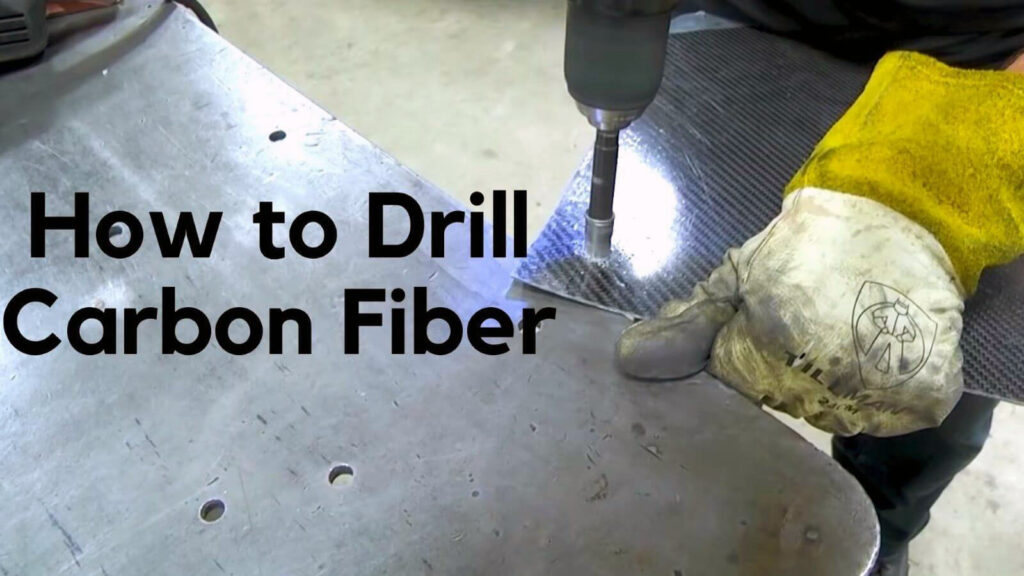

How To Drill Carbon Fiber Step by Step Process

Step 1: Preparing the Work Area

Before drilling into carbon fiber, you need to set up a clean and safe work environment.

- Ensure proper ventilation: Carbon fiber dust is harmful, so make sure you’re working in a well-ventilated area, or use a dust extraction system.

- Protective gear: Wear gloves, safety glasses, and a dust mask or respirator to prevent inhaling harmful particles.

- Work surface: Place the carbon fiber sheet on a stable, flat surface with a scrap backing material like wood or a foam sheet to support the material and reduce fraying.

Step 2: Cutting the Carbon Fiber Sheet

If your project requires cutting before drilling, it’s essential to do it right. Use a diamond blade or a carbide-tipped saw to make clean cuts. Cut slowly and steadily to avoid creating cracks or frays along the edges. If the sheet is small or fragile, secure it using clamps to avoid movement during cutting.

Step 3: Drilling the Holes

Once you’re ready to drill, follow these steps for a precise, clean cut:

- Mark the hole location: Use a marker or masking tape to identify where you want to drill.

- Pre-drill a pilot hole: For larger holes, drill a small pilot hole first to guide the larger bit. This reduces stress on the material.

- Slow and steady drilling: Use a slow RPM speed and apply light pressure. Going too fast can cause the material to overheat, leading to cracking or fraying.

Step 4: Insert the Screw

Once the holes are drilled, you can insert the screws. Be cautious while tightening them, as overtightening can lead to stress fractures in the carbon fiber. If necessary, you can reinforce the area around the screw holes with a washer or a similar device.

Step 5: Sand and Finish

After drilling, the edges of the holes may need to be sanded to eliminate any roughness or fraying. Use fine-grit sandpaper and gently sand the area around the hole for a smooth finish.

Read More: Drilling to Aluminium Step by Step.

How is Carbon Fiber Made?

Carbon fiber is produced by spinning carbon atoms into long, thin filaments, which are then woven into fabric or molded into sheets. These fibers are extremely strong and stiff, and when combined with a resin, they form a composite material that is incredibly lightweight and durable. Drilling into carbon fiber requires care because the fibers are prone to fraying when exposed to high friction or heat.

How to Use Holesaw Drill Bits to Drill Carbon Fiber

When you need to create larger circular holes, such as those for ducts or large bolts, holesaw drill bits with diamond or carbide tips are the best choice. Here’s how to use them:

- Secure the carbon fiber sheet: Use clamps to keep the sheet steady on your work surface.

- Start with a pilot hole: Drill a small pilot hole in the center of your intended cut to help guide the hole saw.

- Drill slowly: Use a slow speed and apply light pressure to avoid overheating the material.

- Cool the drill bit: If the bit gets too hot, cool it down with water to prevent damage to both the bit and the carbon fiber.

How to Drilling a Carbon Fiber Hood

Drilling into a carbon fiber hood, whether for installing vents or attaching hardware, follows a similar process:

- Mark the location: Use masking tape to mark the drilling location and help reduce splintering.

- Use a backing material: Place foam or plywood behind the hood to support the material.

- Slow, steady drilling: Apply light pressure and drill at low RPM.

- Check your bit frequently: Ensure your bit remains sharp and cool to avoid fraying the hood.

How can Carbon Fiber be Used in Drill?

Carbon fiber itself is not typically used to make drill bits, but it’s frequently drilled for high-performance applications like car parts, aircraft components, and sporting equipment. Its lightweight and strength make it ideal for situations where reducing weight is crucial without sacrificing durability.

What are the Dangers of Working With Carbon fiber?

Drilling or cutting carbon fiber releases fine dust particles that are hazardous to health if inhaled. This dust can cause respiratory issues or skin irritation. Always wear protective gear, including a respirator, when working with carbon fiber. Additionally, working too fast can generate excess heat, causing delamination (the separation of the carbon fiber layers) or cracks.

The benefits of drilling into carbon fiber are many and varied.

High strength: Carbon fiber maintains its strength even when drilled, making it ideal for lightweight structures.

Durability: Properly drilled holes won’t affect the long-term performance of the material.

Disadvantages of Drilling into Carbon Fiber?

Despite its benefits, drilling into carbon fiber does have some drawbacks:

- Fraying: Poorly executed drilling can cause the edges of the holes to fray.

- Health hazards: The fine dust produced during drilling can be harmful if inhaled.

- Cost: High-quality drill bits and specialized tools are often required.

Read More: Experimental analysis of drilling damage in carbon-fibre

Extra Tips For Drilling Carbon Fiber

Use a sharp drill bit: Dull bits will cause fraying or cracking.

Clamp the material: Secure the carbon fiber to prevent movement.

Use low RPM: Slow speeds are essential for minimizing heat and stress on the material.

Safety First:

Working with carbon fiber requires extra precautions:

- Wear protective gear: A dust mask, gloves, and safety glasses are a must.

- Work in a ventilated area: Ensure the workspace is well-ventilated or use a dust extraction system to remove harmful particles.

(FAQs) About How to Drill Carbon Fiber

What is the difficulty level of drilling carbon fiber?

Drilling carbon fiber is moderately difficult due to its abrasive nature. Specialized tools and techniques are required to avoid damage.

How do you avoid fraying the carbon fiber?

Use sharp drill bits, go slowly, and secure the material with masking tape or clamps to prevent fraying.

How are carbon fiber edges finished?

After drilling, lightly sand the edges with fine-grit sandpaper to smooth out any rough or frayed areas.

Conclusion

Drilling carbon fiber can be challenging, but with the right tools, preparation, and techniques, it’s entirely manageable. By following these steps, you’ll ensure clean, accurate holes that maintain the integrity of the material. Just remember to prioritize safety, take your time, and always use the appropriate tools for the job.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.

whoah this blog is wonderful i really like reading your articles. Keep up the great paintings! You realize, a lot of people are hunting round for this info, you could help them greatly.

Thank you so much for your kind words! I’m thrilled to hear that you enjoy reading the articles. I’ll do my best to continue providing valuable information. If there’s anything specific you’d like to know or any topics you’d like me to cover, please let me know. I’m here to assist and help as many people as possible.

Great selection of modern and classic books waiting to be discovered. All free and available in most ereader formats. download free books