Drilling aluminum is making a hole in the aluminum using a drill. The fix is then filled with a particular type of metal, called a drill bit, which helps the aluminum be cut.

With the right tools and techniques, drilling aluminum can be a breeze!

Drilling aluminum can be a challenge. But, with the right tools and a little bit of practice, you can do it like a pro! In this article, I will discuss how to drill aluminum. So let’s Begin.

Table of Contents

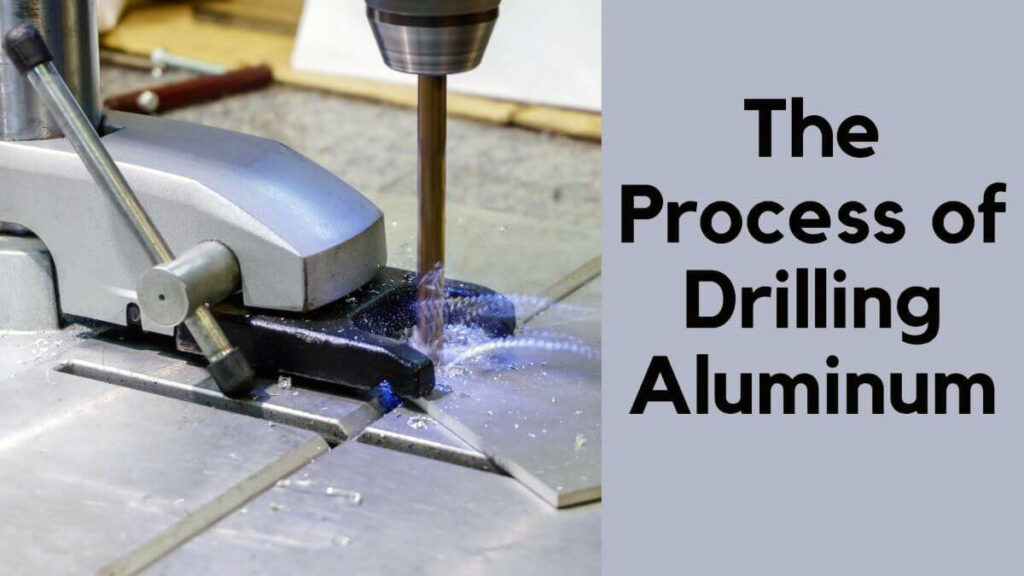

What is the Process of Drilling Aluminum?

Aluminum is a metal that is commonly used in construction and engineering. It is also used in various other industries, such as automotive manufacturing. The process of drilling aluminum uses a rotary drill to create a hole in the metal.

The drill bit is inserted into the hole, and the user then uses a hand-held drill to rotate the bit. This process causes the aluminum to become fractured, which allows it to be removed from the metal.

Read More: How to Drill a Hole Bigger than Your Drill Bit?

What Tools Do You Need to Drill Aluminum?

The tools you will need to drill aluminum are a drill bit, a drill, and a screwdriver. The drill bit should be at least 1/8th inch in diameter, and the screwdriver should be the right size to fit the drill bit.

1. Drill bit

2. Drill bit holder

3. Drill bit chisel

4. Drill bit screwdriver

5. Aluminium saw

6. Aluminum pipe

7. Pencil or highlighter

8. Clamping vises

9. A power drill

10. Dishwashing liquid

Read More: How to Drill into Metal Studs

How To Drill Aluminum Step By Step Process

Step 1: Choose the right drill bit

There are a few factors to consider when choosing the right drill bit for drilling aluminum. The size of the hole, the material’s hardness, and the speed of the drill are all critical factors.

Drilling aluminum can be rugged, so using the right bit for the job is essential. The size of the hole and the material’s hardness are two critical factors to consider.

If the hole is too small, the drill will not penetrate the aluminum and will not hold up well. If the gap is too big, the training will break through the aluminum, not holding up well.

The speed of the drill is also an essential factor. If the training is too slow, the aluminum will not be drilled evenly and will likely result in defects.

For best results, use a drill with at least 1,000 RPM speed.

Step 2: Apply Pressure Evenly

Pressure is critical when drilling aluminum. You need to apply even pressure to avoid creating divots in the metal.

When drilling aluminum, it is essential to apply even pressure to avoid creating divots in the metal. To do this, use a drill bit that is slightly smaller than the diameter of the aluminum pipe you are drilling. This will help prevent the bit from slipping and create divots in the metal.

Step 3: Rotate the Drill Bit

It is essential to rotate the drill bit to prevent the bit from becoming stuck in the aluminum when drilling aluminum.

This step is often overlooked and can damage the drill bit and aluminum. It can also cause a fire if it gets into the drill.

Step 4: Keep the Drill Bit Sharp

Keeping the drill bit sharp is key to drilling aluminum without creating too much wear and tear on the material. Sharpening the bit regularly will help prevent it from becoming dull and causing inaccuracies while preparing.

Step 5: Clean the Drill Bit

- Rinse the drill bit with water.

- Use a wire brush to clean the drill bit.

- Use a polishing cloth to clean the drill bit.

Step 6: Drill in a Slow and Steady Motion

Drilling aluminum in a slow and steady motion is essential to prevent the drill from over-torquing; slow and controlled motion is necessary when drilling aluminum to prevent the exercise from over-torquing. Over-torquing can cause the drill bit to break, resulting in a mess and wasted time.

1. Take your time when drilling.

2. Drill slowly and steadily to avoid making too much noise.

3. Wear ear protection if possible.

4. Make sure to use the correct drill bit for the drilling material.

Check Also: How To Drill A Hole In Silverware

The Pros of Drill Aluminum

1. They are solid and durable.

2. They are lightweight, making them easy to move around.

3. They are affordable, making them a good option for those on a budget.

4. They are easy to work with, making them an excellent choice for DIYers.

5. They are easy to paint or customize, giving you plenty of flexibility when it comes to design.

The Cons of Drill Aluminum

1. It is expensive

2. It is not as strong as other materials

3. It can be challenging to work with

4. It is not as corrosion-resistant as other materials

Read More: How To Drill A Hole In Sea Glass?

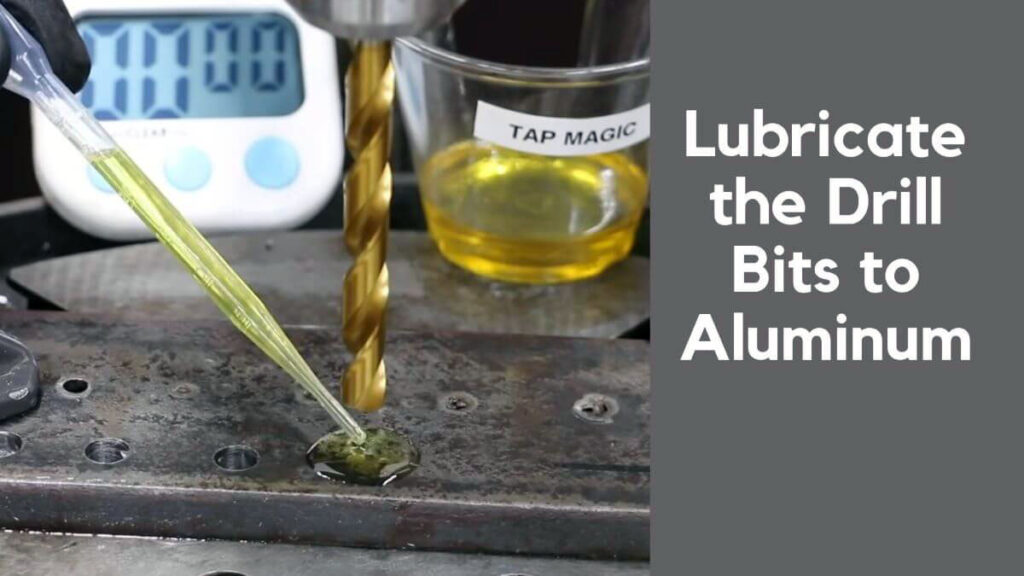

How to Lubricate the Drill Bits to Aluminum

When drilling aluminum, it is essential to use the proper lubricant to avoid metal-to-metal contact and ensure a smooth and accurate drilling experience.

Many drill bits are designed to use a specific type of lubricant, but there are many other options available. Some popular lubricants for aluminum drilling include lithium-based lubricants, synthetic oils, and water-based lubricants.

It is essential to test a small amount of the lubricant on a small piece of aluminium before using it on the entire drill bit.

1. Lubricate the drill bits to aluminium with light oil or grease.

2. Insert the drill bit into the chuck of the drill.

3. Turn on the drill and let it run until the bit is spinning at high speed.

4. Hold the end of the drill bit against the aluminium and apply pressure.

5. Keep rotating the drill bit until it is fully inserted into the aluminium.

Read More: How to Remove a Broken Drill Bit from Aluminum?

How to Make a Hole in Aluminum Without a Drill?

- There are a few ways to make a hole in aluminum without using a drill.

- Use a sharp knife to make a small hole in the aluminum center.

- Place the aluminum sheet on a flat surface and hold it down with your hand.

- Place the drill bit on the sharp end of the drill and hold it against the hole in the aluminum.

- Turn on the drill and start drilling slowly.

- Keep a close eye on the aluminum sheet and stop drilling when you reach the desired depth.

Watch This Video For Learn More –>

The Safety of Drill Aluminum

Drilling aluminium is a safe process, provided you use the appropriate safety equipment and follow the proper guidelines.

- Always wear safety goggles and a dust mask when drilling aluminum, and use a sturdy workbench or stable platform.

- Use a drill bit that is the same size as the hole you are preparing, and make sure the bit is sharpened correctly.

- Never hold the drill while it is spinning; use a handgrip instead.

- Keep your hands and arms well away from the spinning drill bit.

- Use a drill bit guard when drilling into hard materials.

Read More: Can You Bolt Aluminum to Stainless Steel Drill Bits?

Final Word

Even though aluminium is relatively easy to work with, it requires caution when drilling. It is also very pliable and light to be recycled in any condition. Because most drill bits are not designed to penetrate such materials, they either dull or eat through them, ruining your project.

Drilling aluminium can be easy if you follow these simple steps. Remember always to be safe when drilling any material. For more tips and tricks, visit our website.

Hey, I am Shihab Uddin, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.