Attaching a vise to your drill press can make your drilling operations far more efficient and safer. A drill press vise is an essential tool for anyone working with precision machining, metalworking, or even woodworking, as it holds the workpiece securely, allowing you to drill accurately without the material shifting or moving. If you’re wondering how to attach a vise to your drill press, you’ve come to the right place. This ultimate guide will walk you through the process step by step, discuss the types of vises, and share tips for ensuring your vise is secure.

Table of Contents

What is a Drill Press Vise?

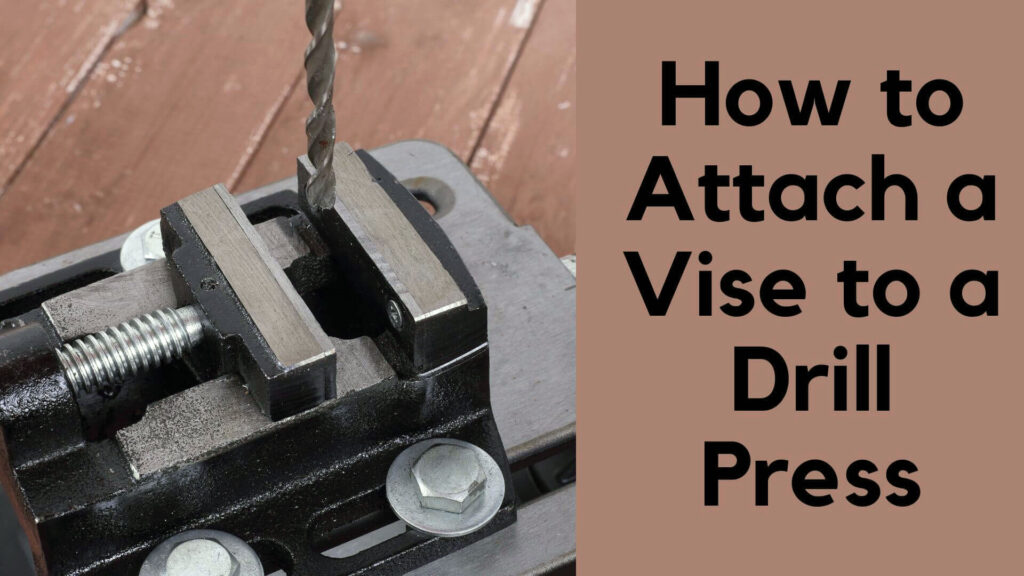

A drill press vise is a specialized tool designed to hold a workpiece firmly in place while you use a drill press. It consists of a flat base and adjustable jaws that clamp down on the material you’re working with. The vise keeps the material steady, reducing the risk of slippage and improving the precision of your drilling.

Drill press vises come in various sizes and types, each suited for different materials and applications. Whether you’re drilling into wood, metal, or plastic, a vise can be adjusted to hold the workpiece securely, giving you better control during the drilling process.

Read More: What is a Radial Drill Press?

What Are The Different Types Of Drill Press Vises?

There are several types of drill press vises available, each with unique features and applications:

- Standard Drill Press Vise: This is the most common type of vise, designed to hold flat and regular-shaped objects. It has two adjustable jaws and is ideal for general-purpose drilling tasks.

- Angle Drill Press Vise: An angle vise allows you to tilt and adjust the angle of the workpiece, which is useful when you need to drill at a specific angle rather than straight down.

- Cross-Slide Vise: This type of vise is ideal for precision work. It features two adjustable slides that allow you to move the workpiece horizontally and vertically without needing to reposition the vise manually. This is often used in metalworking for more intricate tasks.

- Pipe Vise: As the name suggests, a pipe vise is designed specifically for holding round or irregularly shaped materials like pipes and tubing. The jaws are shaped to grip the round surface securely.

- Quick-Release Vise: This type of vise allows you to quickly open and close the jaws, which is useful for tasks that require frequent repositioning or adjustments.

Each of these vises can be attached to a drill press depending on your specific needs and the type of material you’re working with.

Read More: How To Bore A Cylinder With A Drill Press In Just Minutes

How to Attach a Vise to a Drill Press Step by Step

Attaching a vise to your drill press is a straightforward process, but it requires precision and the right tools to ensure it’s mounted securely. Follow these step-by-step instructions to attach your vise correctly:

Step 1: Choose the Vise

First, determine which type of vise is suitable for your task. Consider the size and shape of the workpiece, as well as the type of material you’ll be drilling into. For general-purpose drilling, a standard drill press vise is usually sufficient. However, if you’re working with angled cuts or precision drilling, you may want to opt for an angle or cross-slide vise.

Step 2: Mount the Vise

Next, clean the drill press table to ensure no debris or dirt interferes with the mounting process. Position the vise on the drill press table, aligning it with the center hole of the drill press. Most drill presses have slotted tables that allow you to bolt down accessories like a vise. Make sure the vise is aligned with the spindle of the drill press to ensure accurate drilling.

Step 3: Attach the Vise

To attach the vise securely, you’ll need bolts that fit through the slots in the drill press table. Follow these steps:

Check Alignment: After tightening, double-check the alignment of the vise with the drill bit or spindle. The workpiece should be centered directly under the drill.

Insert Bolts: Place bolts through the base of the vise and the corresponding slots in the drill press table.

Tighten the Nuts: Use nuts to secure the bolts. Tighten them with a wrench or spanner to ensure the vise is locked in place.

Step 4: Drill

With the vise securely attached, place your workpiece between the jaws of the vise. Adjust the jaws to grip the material firmly, but avoid over-tightening, as this could damage delicate materials. Start the drill press and lower the drill bit slowly into the workpiece, allowing the vise to hold the material steady throughout the process.

Step 5: Finish Up

Once your drilling task is complete, raise the drill bit and switch off the drill press. Remove the workpiece from the vise by loosening the jaws. If you’re done using the vise for this project, you can leave it attached to the drill press for future use or remove it by reversing the attachment process.

Read More: How To Use A Drill Press Vise

How Do I Attach A Drill Press Vise To My Drill Press?

The process of attaching a drill press vise to your drill press involves using bolts and clamps to secure it to the table. Make sure that the vise is aligned with the spindle for accurate drilling, and use the correct size bolts to match the slots in your drill press table. Regularly check that the vise remains secure during use to avoid accidents.

Read More: Some Amazing Drill Press Under 100$

How Do I Know If My Vise Insecure?

To check if your vise is securely attached, follow these guidelines:

Material Stability: The workpiece should remain firmly in place throughout the drilling process. If the material shifts or slips, this may indicate the vise is not clamping tightly enough.

Wobble Test: Gently push and pull on the vise after tightening the bolts. If it wobbles or moves, it’s not secure enough. Tighten the bolts further until it remains firmly in place.

Check for Alignment: Visually inspect the alignment between the workpiece and the drill bit. If the alignment shifts while drilling, the vise may need to be tightened or repositioned.

What Are The Benefits Of Using A Drill Press Vise?

Using a drill press vise offers several key advantages:

- Increased Precision: A vise holds your workpiece steady, allowing for more accurate drilling. This is especially important when working with delicate or precise materials.

- Improved Safety: Holding a workpiece by hand can be dangerous when drilling. A vise minimizes the risk of injury by securely holding the material, keeping your hands away from the drill bit.

- Versatility: A drill press vise can hold a variety of materials, including wood, metal, and plastic. It also allows you to work with irregularly shaped objects, such as pipes or tubes, with ease.

- Reduced Fatigue: Manually holding a workpiece in place can be tiring, especially during long or repetitive drilling tasks. A vise takes the pressure off your hands, allowing you to focus on controlling the drill press.

FAQS About How to Attach a Vise to a Drill Press

How do I attach a vise to my drill press?

To attach a vise to your drill press, first select the appropriate vise for your project. Position it on the drill press table, insert bolts through the base of the vise and the slots on the table, and tighten the nuts to secure the vise in place. Ensure it is aligned with the drill press spindle for accurate drilling.

Is a drill press vise necessary for drilling?

While not always necessary, a drill press vise greatly enhances precision, safety, and control during drilling operations. It holds the workpiece steady and prevents movement, which is especially important when working with harder materials or larger projects.

Can I use any type of vise with my drill press?

Not all vises are suitable for drill press use. A dedicated drill press vise is recommended as it is specifically designed to handle the pressure and torque generated by the drill. Additionally, it is designed to be easily mounted to the drill press table.

How do I know if my drill press vise is tight enough?

To ensure your vise is tight enough, conduct a wobble test by gently pushing and pulling on the vise. It should not move. You should also check the stability of the workpiece while drilling—if the material shifts, you may need to adjust the jaws or tighten the bolts.

Last Thought

Attaching a vise to a drill press is a relatively simple but highly effective way to improve your drilling operations. A properly secured vise ensures precision, safety, and stability, allowing you to drill more efficiently and accurately. Whether you’re working on wood, metal, or plastic, investing in a quality drill press vise and following the correct attachment process will pay off in the form of cleaner cuts and better results. By keeping the steps outlined in this guide in mind, you can confidently attach a vise to your drill press and get to work on your next project.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.