When it comes to power tools, choosing the right equipment can make or break a project, especially in demanding drilling operations. One tool that stands out for its efficiency and versatility is the SDS drill. In this post, we’ll explore what an SDS drill is, its history, the different types, and how this tool can benefit your drilling operations. We’ll also address common safety tips and frequently asked questions related to SDS drills.

Table of Contents

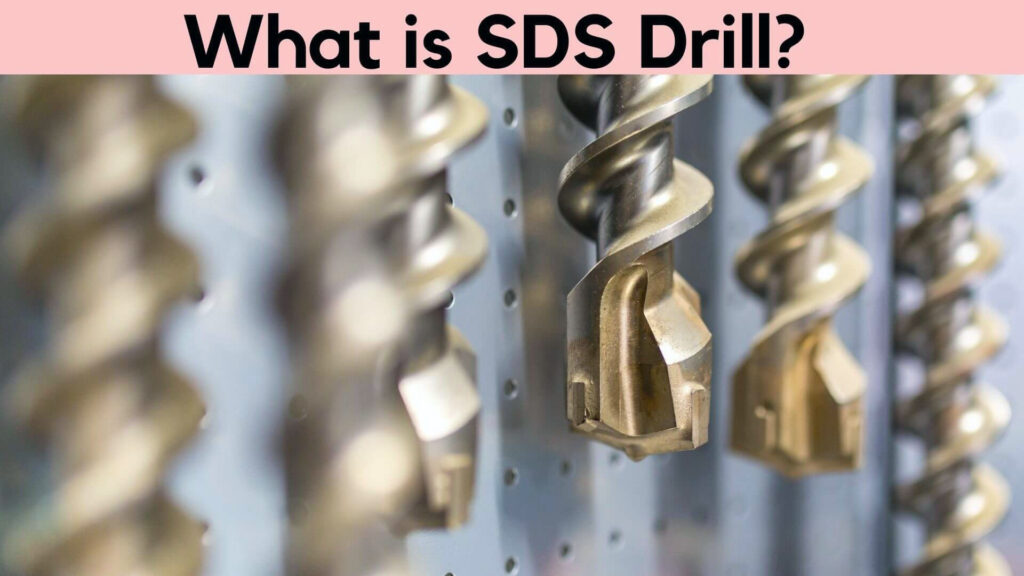

What is an SDS Drill?

An SDS drill, which stands for “Slotted Drive System” or “Slotted Drive Shaft,” is a high-performance hammer drill designed for heavy-duty applications. Unlike standard drills, which rely on rotational force alone, SDS drills use a combination of rotation and hammering action, making them highly effective for drilling into tough materials like concrete, brick, stone, and masonry.

The defining feature of an SDS drill is its unique chuck system, which allows the bit to move freely back and forth while rotating. This design increases drilling power and speed while reducing the amount of effort required by the operator. SDS drills are popular in construction, renovation, and professional handyman tasks, as they excel at tasks where standard drills might struggle.

Check Also: What is Mag Drill and How to Use it?

History of SDS Drill

The SDS drill was first developed by Bosch in 1975 as a solution to the limitations of traditional hammer drills. The need for a more efficient and durable tool for drilling into hard surfaces led to the creation of the SDS system. The slotted design of the chuck and bit allowed for more precise power transfer and better durability, which solved many of the issues caused by bit slippage and wear in conventional drills.

Since its inception, the SDS drill has gone through several iterations, with improvements in power, ergonomics, and safety features. Today, SDS drills are a staple in construction and masonry work, trusted for their ability to handle the most demanding drilling tasks with ease.

Read More: Can A Sds Bit Be Used To Drill Rock?

What are the Different Types of SDS Drills?

SDS drills come in different models, each suited for various tasks depending on the material you’re working with and the kind of holes you need to drill. The two main types of SDS drills are the standard SDS drill and the rotary SDS drill.

- The Standard SDS Drill: A standard SDS drill is designed primarily for heavy-duty drilling into hard surfaces like concrete and brick. These drills combine rotational and hammering actions to deliver high levels of impact energy, allowing them to penetrate tough materials without much resistance. Standard SDS drills are perfect for jobs like installing wall anchors, drilling through masonry, or creating holes for pipes and wiring.

- The Rotary SDS Drill: Rotary SDS drills take things a step further by adding a rotary-only function to the standard hammer drill mode. This means the tool can function as both a hammer drill and a regular rotary drill, depending on the task at hand. Rotary SDS drills are more versatile, making them suitable for a wider range of applications, including drilling through softer materials where you don’t need the hammer action.

What is the Difference Between the Standard SDS Drill and the Rotary SDS Drill?

The key difference between the standard SDS drill and the rotary SDS drill is their functionality. The standard SDS drill is mainly used for hammer drilling, with a strong focus on impact energy to drive through hard materials like concrete. It is best suited for tasks where you need both power and speed in a straightforward manner.

On the other hand, the rotary SDS drill provides greater flexibility. It can switch between modes — you can use it as a hammer drill for tough materials or as a regular drill for lighter tasks. This added functionality makes the rotary SDS drill a more versatile tool, as it can be adapted to a broader range of applications without the need to switch between different tools.

This Video is About Rotary SDS vs Impact Drills ->

What are the Other Features of the Rotary SDS Drill?

Rotary SDS drills come with several additional features that make them even more versatile and user-friendly:

- Mode Selector Switch: Many rotary SDS drills come with a mode selector that allows users to switch between drilling, hammer drilling, and chiseling. This adaptability makes them useful for tasks like light demolition work or removing old tiles.

- Variable Speed Control: The speed control feature on many rotary SDS drills allows for precision drilling in various materials. Lower speeds are useful for delicate work, while higher speeds offer more power for heavy-duty tasks.

- Depth Stops: Rotary SDS drills often come equipped with depth stops, allowing you to control the depth of the hole being drilled, which is particularly useful in applications requiring precise measurements.

- Vibration Control: Some rotary SDS drills have vibration control mechanisms that reduce the amount of vibration felt by the user. This makes prolonged drilling more comfortable and reduces fatigue.

- Quick Change Chuck: The SDS chuck system allows for easy and quick bit changes without the need for tools, improving efficiency on the job site.

What are the Benefits of Using an SDS Drill?

SDS drills provide several benefits, making them the go-to tool for professionals in construction and heavy-duty DIY projects. Here are some of the key benefits:

1. Efficient Drilling in Hard Materials

The hammer action of an SDS drill allows for quick and efficient drilling in hard materials like concrete, stone, and brick. The combination of rotation and hammering ensures that the bit penetrates the surface with minimal effort.

2. Durability

The SDS system is designed for long-term use, with bits that are less likely to wear out quickly compared to traditional drills. The slotted design reduces bit slippage, resulting in a longer lifespan for both the drill and the bits.

3. Versatility

Rotary SDS drills offer multiple modes for different tasks, making them suitable for everything from drilling into hard materials to performing light chiseling and demolition work. This versatility saves time and reduces the need for multiple tools.

4. Reduced Operator Fatigue

SDS drills are designed to reduce the amount of force needed to drill through tough materials, meaning less strain on the operator. The vibration control and ergonomic designs found on many models also help reduce fatigue during extended use.

5. Quick Bit Changes

The SDS chuck system allows for fast and tool-free bit changes, improving efficiency and productivity on the job site. This feature is especially useful when switching between tasks that require different types of bits.

Think About Safety

When using an SDS drill, it’s important to prioritize safety. Here are a few key safety tips to keep in mind:

- Wear Safety Gear: Always wear protective goggles, gloves, and hearing protection when using an SDS drill, especially when drilling into hard materials that can create flying debris.

- Use the Right Bit: Make sure to use the appropriate SDS bit for the material you’re working with. Using the wrong bit can lead to poor results and may damage both the drill and the material.

- Secure the Material: Ensure that the surface or object you’re drilling into is securely fastened or stable to avoid accidents or uneven drilling.

- Follow Manufacturer Instructions: Always follow the manufacturer’s instructions for proper operation and maintenance of your SDS drill.

Check Also: How To Drill In Cast Iron Like a Pro

FAQS About What is SDS Drill?

What is the difference between hammer drills and SDS?

A standard hammer drill uses a simple hammering motion combined with rotation, while an SDS drill utilizes a more powerful hammer mechanism and specialized chuck system. This allows SDS drills to handle much tougher materials like concrete, making them more effective for heavy-duty applications.

What does the SDS on a drill stand for?

SDS stands for “Slotted Drive System” or “Slotted Drive Shaft.” It refers to the way the drill bit attaches to the chuck, allowing for efficient transfer of power and easier bit changes.

Can a regular drill bit be used in an SDS drill?

No, standard drill bits are not compatible with an SDS drill. SDS drills require special SDS bits that have slots designed to fit into the SDS chuck system. However, some SDS drills come with a quick-change chuck that allows you to use standard bits when necessary.

Can I use a carbide-tipped drill bit in an SDS drill?

Yes, you can use a carbide-tipped drill bit in an SDS drill, as long as it is designed for SDS systems. Carbide-tipped bits are great for drilling through hard materials like concrete and stone.

Final Word

SDS drills are a versatile and powerful tool that can significantly improve your drilling operations, especially when working with tough materials like concrete and brick. Whether you’re a professional contractor or a DIY enthusiast, the benefits of using an SDS drill, such as increased efficiency, durability, and ease of use, make it a worthwhile investment.

By understanding the differences between standard SDS drills and rotary SDS drills, and following safety precautions, you can tackle any heavy-duty drilling task with confidence and precision. With their advanced features and reliable performance, SDS drills are essential tools for anyone involved in construction, renovation, or masonry work.

Hey, I am MD Hrithik Hossain, I’m a huge fan of DIY crafts. My workshop is where I spend most of my spare time, and I’m always working on some project. To that end, I’d like to share some of my knowledge and experience with you in power tools, woodworking, and other specialized materials fabrication.

I will guide you with genuine knowledge that can assist you with deciding whether a drill is appropriate according to your requirements or not. If you want to find the best drill and know which type of drill is most suited for your needs, then I can guide you with my expertise. My passion lies in helping others find the correct products they need at an affordable price.